There’s a significant shift occurring in the workforce as cobots, or collaborative robots, emerge as key players in addressing labor shortages across various industries. You may find that these advanced machines are designed to work alongside you, enhancing productivity and efficiency without replacing the human touch. As you explore the potential of cobots, you’ll discover their ability to take on repetitive tasks, allowing you and your team to focus on more complex and creative responsibilities, ultimately driving innovation and growth in your business.

Understanding Cobots

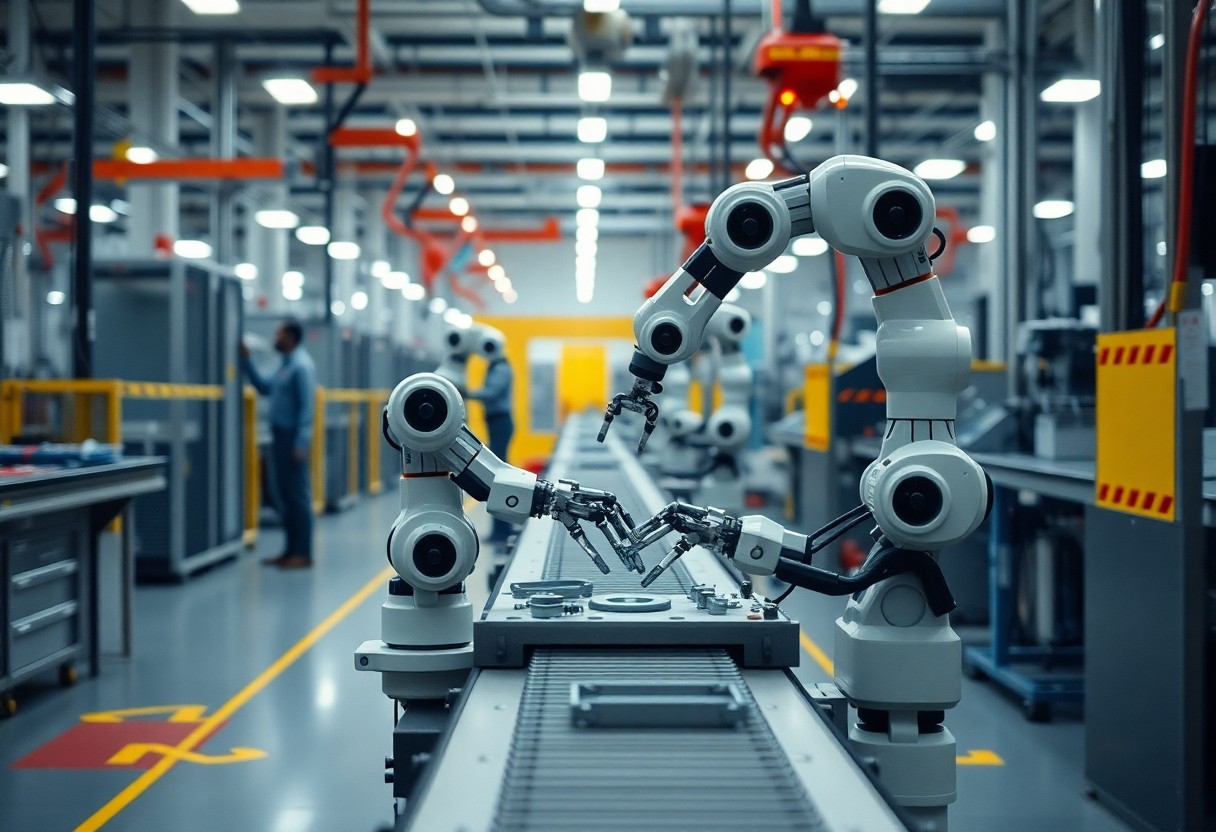

Cobots, or collaborative robots, are designed to work alongside humans in a shared space, enhancing productivity and safety in various workflows. Unlike traditional industrial robots, cobots are equipped with advanced sensors and safety mechanisms, making them safer to operate in proximity to human workers. This synergy allows you to leverage technology without sacrificing human engagement, redefining efficiency across industries.

Definition and Characteristics

Cobots are robotic systems that are specifically engineered for direct interaction with human operators. They feature lightweight construction, user-friendly interfaces, and integrated safety features such as force limits and emergency stop mechanisms. These characteristics ensure that you can easily program cobots for a multitude of tasks, making them ideal for varied applications in manufacturing, logistics, and more.

Types of Collaborative Robots

Various types of cobots exist, tailored for different applications and environments. Some common categories include lightweight robots, which are easy to move; dual-arm robots, designed for complex tasks; and mobile cobots, which can navigate autonomously. You will find specialized versions that adapt to specific industries or functions, such as assembly lines or surgical procedures.

| Type | Description |

| Lightweight Robots | Designed for easy maneuverability and simple tasks. |

| Dual-Arm Robots | Capable of performing intricate tasks requiring dexterity. |

| Mobile Cobots | Autonomously navigate and perform tasks in various environments. |

| Heavy-Duty Cobots | Built to handle heavy materials or perform strenuous tasks. |

| Specialized Cobots | Engineered for specific industries or functions. |

Understanding the various types of cobots is important for leveraging their capabilities in your operations. For instance, lightweight robots excel in repetitive assembly tasks that require speed and accuracy, while dual-arm robots can manage more complex procedures that mimic human hands. Mobile cobots enhance logistics by transporting goods efficiently within facilities. Specialized cobots may include those tailored for delicate environments, like surgeries or electronic assembly. Thou shall explore diverse options for optimal fit.

- You can integrate them into existing workflows seamlessly.

- They’re designed to adapt to different tasks with minimal reconfiguration.

- Collaboration capabilities enhance safety and flexibility in operations.

- Real-time data collection and feedback empower decision-making.

- Thou can choose from different types based on your unique needs.

| Feature | Benefit |

| User-Friendly Interfaces | Quick adoption by workers with varying technical skills. |

| Force-Limit Technology | Enhanced safety during human-robot interaction. |

| Adaptable Programming | Flexibility to perform multiple operations without extensive retraining. |

| Compact Design | Easier integration into limited workspace environments. |

| Collaborative Features | Increased efficiency through direct human-robot teamwork. |

The Labor Gap Challenge

The challenge of workforce shortages has become increasingly evident, leaving businesses struggling to meet productivity demands. With millions of job openings unfilled, companies face delays and reduced output, hindering growth. Your organization may be among those affected by the rising challenge of attracting qualified personnel, often leading to increased operational costs and potential declines in service quality.

Current Workforce Shortages

Workforce shortages have significantly intensified across various sectors, with an estimated 10 million job vacancies in the U.S. alone as of 2023. You may find it difficult to navigate a landscape where talent acquisition is more competitive than ever, resulting in longer recruitment cycles and higher salaries necessary to attract scarce talent.

Industries Most Affected

Certain industries are grappling more than others with workforce shortages, notably manufacturing, healthcare, and logistics. You’re likely to observe how these sectors are struggling to fill vital roles, impacting their operations and service capabilities.

In manufacturing, for instance, the sector is projected to need 2.1 million new workers by 2030, exacerbated by a retiring workforce and insufficient interest in skilled trades. Healthcare, too, faces alarming shortages, with a predicted deficit of 3 million workers by 2032 due to an aging population requiring care. Logistics, as e-commerce continues to boom, is unable to keep pace with demand, leading to delivery delays and compromised service. Adapting to these challenges through solutions like collaboration with cobots can help mitigate the impact on your business.

Benefits of Human-Robot Collaboration

Human-robot collaboration offers multifaceted advantages that significantly elevate workplace efficiency and employee well-being. By integrating cobots into your operations, you not only enhance productivity but also foster a safer and more ergonomic work environment. This synergy between humans and robots can streamline workflows, minimize repetitive tasks, and ultimately lead to a more engaged workforce, driving excellence in your business outcomes.

Increased Productivity

Utilizing cobots enables you to boost productivity by automating mundane, time-consuming tasks. Research shows that companies adopting these robots have experienced an average productivity increase of 20-30%. By handling routine operations, cobots allow your workforce to focus on complex problem-solving and innovative projects, enhancing overall output and achieving more in less time.

Enhanced Safety and Ergonomics

With cobots in your workspace, you can significantly improve safety and ergonomics. These robots are designed to perform hazardous tasks and relieve employees from strenuous activities, which often lead to injuries. By minimizing physical strain, you create a healthier work environment, reducing the incidence of workplace accidents and fostering a culture that prioritizes employee welfare.

Evidence supports that factories employing cobots saw a 50% reduction in workplace injuries within the first year of implementation. For example, in an automotive assembly line, cobots handle heavy lifting and repetitive motions, freeing workers to engage in strategic tasks, thereby minimizing muscle strain and fatigue. In turn, this leads to greater job satisfaction and lower turnover rates, benefiting both your organization and its employees.

Implementing Cobots in the Workplace

Integrating cobots into your workplace involves careful planning and consideration of your specific operational needs. Start by identifying repetitive tasks that could benefit from automation, allowing your employees to focus on more complex responsibilities. Ensuring seamless interaction between humans and robots is vital to maximizing productivity, which may involve investing in compatible technology and modifying workflows to accommodate these new tools.

Integration Strategies

To successfully integrate cobots, you should choose systems that are adaptable and easy to implement. Begin with pilot programs in localized areas of your operations to assess effectiveness before scaling up. Collaborate with technology providers to customize the deployment, ensuring alignment with your operational goals and workforce capabilities.

Training and Adaptation

Effective training is crucial for your team to collaborate with cobots confidently. Introduce hands-on training sessions that focus on how to program, operate, and troubleshoot these machines. Adaptation to this technology involves not just technical skills, but also cultivating a culture of collaboration between humans and machines.

Training programs for cobots should be ongoing, encompassing both initial instruction and refreshers as technologies evolve. Incorporating real-world scenarios helps employees grasp the practical applications of cobots in their specific roles. Utilizing virtual reality or simulations can enhance learning experiences, allowing your team to engage with cobots in a risk-free environment. Collect feedback regularly to make necessary adjustments and ensure continuous improvement, fostering an adaptable workforce ready to embrace technological advancements in the workplace.

Case Studies in Cobot Implementation

Examining real-world applications of cobots reveals their transformative impact across various industries. These case studies demonstrate significant efficiency gains and labor savings.

- A German automotive manufacturer increased productivity by 20% after implementing cobots on the assembly line.

- A U.S.-based electronics company reduced defects by 30% and increased output by 40% with collaborative robots.

- A logistics firm reported a 50% reduction in order fulfillment time after deploying cobots in their warehouse.

- A construction site employing cobots was able to complete projects 25% faster, addressing labor shortages effectively (Solving the Construction Worker Shortage: How Robotics …).

Manufacturing Success Stories

Your insights into manufacturing reveal that companies leveraging cobots have achieved substantial improvements in production efficiency. A notable example includes a metal fabrication company that shortened cycle times by 40%, allowing for increased output and reduced labor costs.

Service Industry Innovations

In the service sector, cobots are streamlining operations and enhancing customer experience. From restaurants using robotic servers to healthcare facilities employing robots for logistics, these innovations are reshaping service delivery.

Noteworthy examples in the service industry include a leading fast-food chain where robots now manage 70% of order processing, boosting efficiency and improving customer satisfaction. Similarly, hospitals deploying cobots for medication dispensing and logistics have reduced human error while allowing staff to focus more on patient care. These applications underscore how robotics can effectively address labor shortages while enhancing service quality.

Future Trends in Cobot Development

As industries adapt to shifting labor dynamics, you can expect significant advancements in cobot development, fundamentally changing how businesses operate. Enhanced artificial intelligence and machine learning capabilities will allow cobots to learn and improve from their interactions, leading to higher efficiency and adaptability. You’ll see increased integration with IoT devices, creating a more interconnected and responsive workplace. These innovations will not only streamline operations but also open up new applications in various sectors, making cobots an imperative part of future workforce strategies.

Advances in Technology

Emerging technologies are driving a remarkable evolution in cobots, enabling them to perform more complex tasks with increased precision. Enhanced sensors and vision systems allow for greater environmental awareness, while improved algorithms enhance decision-making capabilities. For example, cobots can now understand and execute tasks in real-time, adapting to changes in their surroundings. These technological leaps ensure that you can rely on your cobots to seamlessly integrate into various workflows.

Evolving Workforce Dynamics

The incorporation of cobots into the workforce is reshaping job roles and responsibilities across sectors. As these machines take on repetitive and physically demanding tasks, you’ll find that your workforce can focus on more skilled and strategic roles. This transition not only increases job satisfaction but also fosters a more innovative company culture, allowing human workers to engage in problem-solving and creativity. Studies show that businesses utilizing cobots report a 20% increase in employee engagement and overall productivity.

The changing landscape of your workplace is reflected in the evolving dynamics between human workers and cobots. Rather than perceiving cobots as replacements, you can view them as tools that enhance your team’s capabilities. With cobots handling mundane tasks, your employees can develop new skills and take on more complex challenges. This paradigm shift not only promotes job security but also encourages continuous learning and adaptability, crucial in today’s fast-paced economy. Embracing this collaboration will position your organization at the forefront of innovation, increasing both competitiveness and morale.

To wrap up

With this in mind, you can see how cobots are transforming the workforce by effectively bridging the labor gap through enhanced human-robot collaboration. By integrating these intelligent machines into your operations, you not only increase efficiency but also empower your workforce to focus on higher-value tasks. Embracing this innovation will enable you to stay competitive in a rapidly evolving market, fostering a future where technology and human skills complement each other seamlessly.