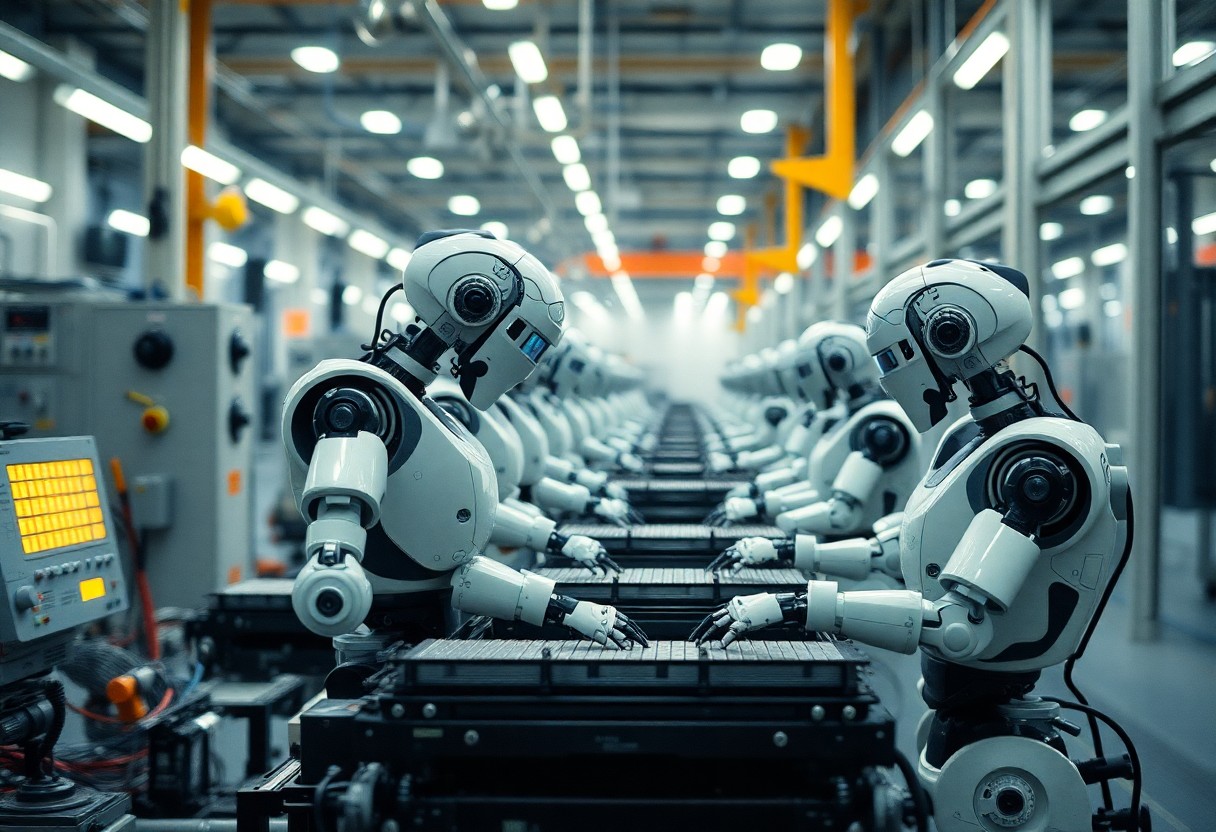

Many industries are embracing sustainability through the integration of energy-efficient robots in manufacturing processes. By optimizing energy consumption and reducing waste, these advanced machines not only enhance productivity but also contribute to your green initiatives. As you explore the impact of automation on sustainable practices, you’ll discover how cutting-edge technology plays a pivotal role in fostering eco-friendly production environments, ultimately driving both economic and environmental benefits for your business.

The Role of Automation in Sustainable Manufacturing

Automation plays a pivotal role in transforming traditional manufacturing processes into sustainable ones by minimizing waste, optimizing energy usage, and enhancing overall productivity. You leverage advanced technologies to streamline operations, making it possible to reduce the carbon footprint of manufacturing activities while improving efficiency and quality. In an era where sustainability is a business imperative, automation becomes your key ally in achieving environmental goals without sacrificing profitability.

Definition of Sustainable Manufacturing

Sustainable manufacturing refers to the creation of products through economically viable processes that minimize negative environmental impacts while conserving energy and natural resources. This approach embraces a holistic strategy, incorporating eco-friendly practices throughout the product lifecycle-from design and sourcing to production and disposal. You engage in this practice to meet customer expectations for sustainability while ensuring long-term business viability.

Impact of Automation on Resource Efficiency

Automation significantly enhances resource efficiency by optimizing production processes, reducing waste, and conserving energy. You can implement automation technologies to monitor resource usage in real time, enabling precise adjustments that minimize excess consumption. Furthermore, robots and automated systems work continuously, allowing for higher output with lower energy input, thereby improving your overall sustainability profile.

For instance, by using automated monitoring systems, you can track energy consumption patterns and identify inefficiencies. A study noted that factories adopting advanced automation experienced a 20% reduction in energy usage and a similar decrease in material wastage. Robotics in manufacturing can precisely cut materials to size, reducing scrap, while predictive maintenance can avert downtime and extend equipment life. These improvements directly translate to a greener manufacturing process, showcasing how automation drives significant resource efficiency gains while aligning with sustainability objectives.

Energy-Efficient Robots: An Overview

Energy-efficient robots are revolutionizing manufacturing processes by minimizing energy consumption while maximizing output. These advanced machines integrate innovative technologies that not only reduce operational costs but also promote sustainability. By utilizing regenerative braking, optimized motion paths, and energy-efficient components, these robots contribute to a significant decrease in the overall energy footprint of production facilities, aligning with global green manufacturing goals.

Types of Energy-Efficient Robots

Understanding the types of energy-efficient robots is important for effective implementation in your operations. They can be categorized as follows:

- Collaborative Robots (Cobots)

- Industrial Robots with optimized drive systems

- Mobile Robots for logistics and warehousing

- Articulated Robots with energy-saving features

- Delta Robots for high-speed applications

Thou must consider each type’s specific advantages to enhance your manufacturing efficiency.

| Type | Key Feature |

| Collaborative Robots | Designed to work alongside humans |

| Industrial Robots | High precision with reduced energy needs |

| Mobile Robots | Energy-efficient navigation systems |

| Articulated Robots | Advanced energy-saving motors |

| Delta Robots | Fast, lightweight for minimal energy use |

Technological Advancements in Robotics

Continuous technological advancements in robotics have significantly enhanced energy efficiency in manufacturing. Innovations such as machine learning algorithms allow robots to optimize their operational performance based on real-time data. For example, integrating smart sensors helps robots identify redundant movements, thereby conserving energy during repetitive tasks. Additionally, advancements in battery technology are enabling more energy-dense power supplies, allowing for longer operational periods without the need for recharging.

Benefits of Energy-Efficient Robots

Energy-efficient robots enhance operational productivity while minimizing environmental footprints, allowing manufacturers to achieve both economic and ecological objectives. By leveraging advancements in robotics, you can optimize workflows and reduce energy consumption significantly. For more insights, check out how energy-efficient robotics changes the game for manufacturers.

Cost Savings and ROI

Investing in energy-efficient robots leads to substantial cost savings over time. These robots consume less power, resulting in lower energy bills and reduced operational costs. Additionally, many come with longer lifespans and require less maintenance, contributing to a higher return on investment (ROI). You’ll often find that the initial expense is offset by the savings realized in operational efficiency.

Environmental Impact

Utilizing energy-efficient robots significantly reduces carbon footprints and waste during manufacturing processes. By minimizing energy consumption and optimizing resource use, you contribute to sustainability goals. These robots often use advanced technology to operate at peak efficiency, which translates to lower emissions and a smaller environmental impact overall.

Specifically, in a study by a leading robotics manufacturer, facilities employing energy-efficient robots reported a reduction in energy consumption by up to 30%, showcasing their potential to drastically mitigate environmental harm. Moreover, industries adopting these innovations are frequently recognized and incentivized under various green initiatives, further motivating your transition to sustainable practices. Harnessing the capabilities of these robots not only benefits your bottom line but also aligns your operations with a more sustainable future.

Case Studies: Successful Implementations

Real-world applications highlight the transformative potential of energy-efficient robots in manufacturing. By examining specific case studies, you can appreciate the significant advancements achieved through green automation strategies.

- Company A reduced energy use by 30% after integrating collaborative robots, leading to annual savings of $500,000.

- Manufacturer B increased production efficiency by 40% by implementing autonomous robots in its assembly line.

- Firm C achieved a 25% decrease in carbon emissions and a 20% reduction in operational costs through the utilization of energy-efficient automation technology.

- Business D realized a 50% reduction in downtime, contributing to a 15% boost in overall productivity with their new robotic systems.

Industry Leaders Adopting Green Robots

Major companies like Tesla and Siemens are leading the charge in adopting energy-efficient robotic systems. These industry giants are setting benchmarks by integrating advanced automation technologies, enhancing efficiency, and demonstrating significant cost reductions alongside reduced environmental impact.

Measurable Outcomes of Energy Efficiency

Tracking energy efficiency yields impressive results. You’ll find measurable outcomes from established implementations showing substantial reductions in energy consumption and operational costs, reaffirming the value of investing in sustainable robotic solutions.

Among prominent outcomes, Tesla’s factory showcases a remarkable 30% decrease in electricity usage since adopting energy-efficient robots. Similarly, Siemens reported a cumulative saving of €10 million in energy costs over five years through their automated systems. These figures underline how energy efficiency is not only beneficial for the environment but also translates into tangible financial savings and heightened competitiveness in today’s market. Organizations that embrace energy-efficient technologies stand to gain a significant advantage as sustainability becomes central to manufacturing practices.

Challenges in Integrating Energy-Efficient Robotics

Even with the promising advantages of energy-efficient robotics, numerous challenges can hinder their widespread adoption in manufacturing environments. From technical limitations to economic implications, overcoming these barriers is vital for a successful transition towards green automation. Understanding these challenges allows you to devise strategies for integration that align with sustainability goals.

Technical Barriers

Technical barriers often include the existing infrastructure not being compatible with new robotic technologies. Legacy systems may struggle with integrating advanced energy-efficient robots, leading to increased costs and extended downtime during implementation. Furthermore, the complexity of programming and managing these robots can impede ease of use, necessitating specialized skills that may not be readily available within your workforce.

Economic Considerations

Economic factors play a significant role in the adoption of energy-efficient robots. While the long-term savings on energy costs are appealing, the upfront investment required for purchasing and integrating these technologies can be a substantial barrier for many manufacturers. You must evaluate the return on investment (ROI) carefully, factoring in potential subsidies or incentives that could offset initial expenditures.

The upfront costs of energy-efficient robots can often exceed traditional alternatives, making budget constraints a major consideration. For instance, while you might save 30% on energy consumption annually, the capital required for robotics can take years to recoup. Additionally, fluctuations in government incentives and subsidies can create unpredictability in planning future investments. Assessing the total cost of ownership, including maintenance and training, is critical in determining whether the switch to energy-efficient robotics aligns with your financial strategy. Leveraging case studies of successful implementations can help provide a clearer picture of potential economic benefits and guide your decision-making process.

Future Trends in Sustainable Automation

As you explore the future landscape of sustainable automation, anticipate a surge in advancements that push the boundaries of energy efficiency. Innovations will focus on integrating artificial intelligence and machine learning to optimize robotic performance while minimizing energy use. Expect to see a broader adoption of smart grids and renewable energy sources that power these automated systems, further aligning manufacturing processes with sustainability goals.

Innovations on the Horizon

You can look forward to groundbreaking technologies such as bio-inspired robotics and energy-harvesting systems that capture and reuse energy. These innovations not only reduce reliance on external power sources but also enhance machinery longevity and efficiency. Organizations adopting these solutions will likely see a significant decrease in operational costs and an improved carbon footprint.

The Role of Policy and Regulation

Policies promoting sustainability will increasingly shape the automation industry, driving manufacturers to adopt eco-friendly practices. Legislation aimed at reducing greenhouse gas emissions will incentivize your organization to invest in energy-efficient technologies, empowering you to meet regulatory standards while enhancing your brand’s reputation.

Policies and regulations not only create a framework for sustainability but also foster innovation within the automation sector. Governments worldwide are implementing stricter environmental standards, pushing companies to prioritize energy-efficient solutions. The European Union, for instance, has introduced the Green Deal, which aims to make Europe climate-neutral by 2050. As you adapt to these regulatory changes, you’ll find that aligning your operations with sustainable practices can lead to competitive advantages, financial incentives, and a stronger commitment to corporate social responsibility.

To wrap up

Now, as you consider the role of energy-efficient robots in green manufacturing, it becomes evident that their adoption not only enhances operational efficiency but also significantly contributes to sustainability goals. Implementing these advanced technologies allows you to reduce waste, lower energy consumption, and minimize your carbon footprint, thereby positioning your manufacturing processes as eco-friendly. Embracing this shift not only meets market demands but strengthens your commitment to environmental stewardship for a more sustainable future.