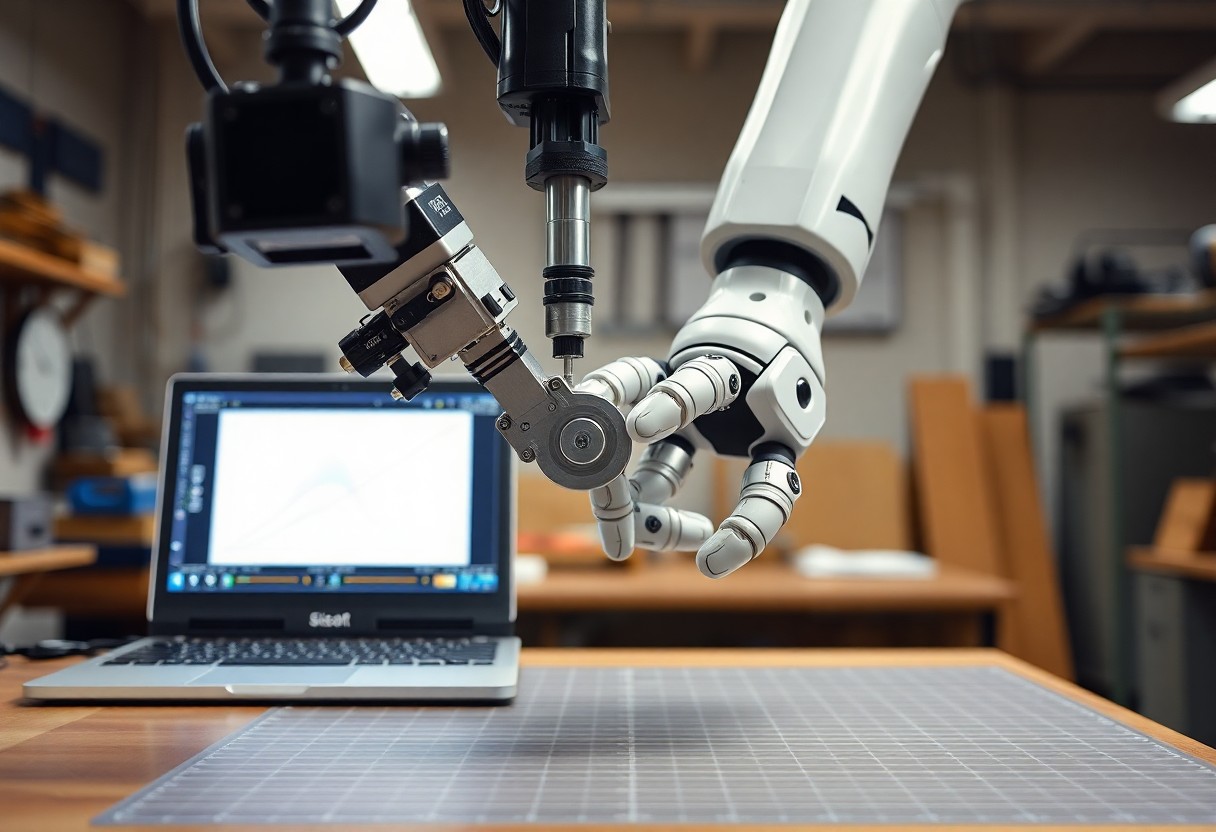

Knowledge of expert techniques and tacit decisions can be encoded to make robots reliably reproduce complex tasks; you learn methods for extracting demonstrations, modeling intent, and translating human heuristics into sensor-driven policies, while assessing robustness, safety, and adaptivity. This guide shows how to structure interviews, use teleoperation and learning-from-demonstration, validate skill generalization, and integrate human oversight so your robotic systems retain expert judgement in dynamic environments.

Understanding Human Skill Transfer

When you translate tacit human skills into robotic controllers, you focus on timing, force profiles, trajectories and decision heuristics; quantifying these often means measuring millisecond timing, Newton-level forces, and sub-millimeter positioning. In manufacturing case studies, encoding expert motions reduced defect rates by 25% and cycle time variability by 35%, showing how precise modeling of human nuance materially improves robot performance.

Definition and Importance

You should view human skill transfer as the process of extracting and formalizing tacit expertise-sensory cues, motor patterns, and decision rules-into machine-interpretable representations. This reduces learning time, increases repeatability and helps robots handle edge cases; for example, in precision assembly, transferring expert strategies cut operator training from weeks to days and lowered part rejection rates by about 30%.

The Role of Expert Knowledge

Experts supply heuristics, exceptions and sensory interpretations that raw demonstrations miss, so you rely on their annotated failure modes, contextual judgments and prioritized cues to shape models. In robotic suturing studies, expert-provided force thresholds and stitch timing improved success rates by roughly 15%, while in welding, operator micro-adjustments for heat flow explain most quality gains.

You capture that knowledge through demonstrations, verbal protocols and dense sensor recordings-IMU, force-torque, stereo vision-and then encode it with techniques like dynamic movement primitives, inverse reinforcement learning or Gaussian processes. Practically, collecting 30-50 demonstrations from 3-5 experts yields robust generalization, and active learning can reduce required demos by the order of 50-60% by targeting ambiguous states.

Mechanisms of Skill Transfer

You leverage multiple channels to transfer expertise: imitation (behavioral cloning), inference (inverse reinforcement learning), and guided practice (teleoperation with haptic feedback). Behavioral cloning often demands thousands of labeled demonstrations, while IRL extracts latent objectives so your robot can generalize across contexts. Methods like DAGGER mitigate compounding errors by incorporating corrective queries. Curriculum learning and reward shaping accelerate convergence by sequencing tasks from simple to complex, and multimodal recordings (vision, force, audio) let you capture both explicit actions and subtle cues that shape expert performance.

Cognitive Processes Involved

You depend on attention allocation, working memory (roughly 7±2 chunks), chunking and proceduralization to encode skills; experts compress sequences into motor primitives so fewer cognitive resources are needed during execution. Mirror-neuron systems support observational encoding, while predictive internal models let you simulate outcomes before acting. In robotics, mapping human demonstrations into latent representations preserves these cognitive structures, enabling transfer of task hierarchies and tempo – for example, breaking assembly tasks into 3-7 reusable subtasks speeds policy learning.

Emotional and Social Aspects

You respond strongly to social signals: trust, perceived competence, and instructor feedback modulate engagement and retention. Social facilitation can boost performance on practiced tasks, and affective cues (tone, gaze, encouragement) influence your willingness to persist through errors. In HRI, robots perceived as warm and competent increase compliance with demonstrations, so you should design interaction protocols that signal intent clearly and maintain consistent, timely feedback to sustain motivation during skill acquisition.

You can apply self-determination principles-supporting autonomy, competence, and relatedness-to scaffold learning: offer adjustable assistance levels, set incremental goals, and provide peer or mentor comparisons. Practically, embed multimodal affect sensing (facial expression, posture, galvanic response) to adapt guidance; schedule faded haptic support so you progressively withdraw assistance; and log confidence estimates with each demo to weight examples when training policies, which preserves motivated engagement and speeds robust transfer in real-world deployments.

Techniques for Capturing Expert Knowledge

You combine observational, interview, and data-driven methods to translate tacit expertise into formal models; for example, video+IMU recordings, task decompositions, and annotated decision trees let you capture timing, intent, and failure modes so controllers and planners can reproduce expert strategies in real environments.

Observation and Analysis

You deploy video (60 fps+), force/torque sensors, and event logs to detect micro-actions and micro-pauses under 100 ms, then annotate with tools like ELAN or BORIS; time-motion studies often reveal inefficiencies and edge-case handling that would be missed by manuals alone.

Structured Interviews and Knowledge Elicitation

You run 3-5 focused sessions of 45-90 minutes using cognitive task analysis, the Critical Decision Method, and think-aloud prompts to extract decision criteria, heuristics, and failure recovery steps that experts no longer verbalize in routine work.

You deepen elicitation with scenario walkthroughs, card-sorting of actions, and retrospective video-assisted recall so experts point out hidden cues; afterwards you encode responses into 30-50 element task models, validate by cross-checking with logged behavior, and iterate until inter-rater agreement on key decisions exceeds your target (commonly 0.7-0.8 kappa).

Implementing Knowledge into Robotic Systems

You map expert heuristics into modular software pipelines that respect hardware limits and verification protocols: run low-level control loops at 1 kHz with latency under 5 ms, expose decision logic via ROS2 nodes, validate motion planners in simulation with 10,000 randomized scenarios, and maintain CI tests that catch regressions before deploying to physical arms or mobile bases.

Programming and Algorithms

Adopt hybrid architectures combining behavior trees for high-level sequencing, finite-state machines for error handling, and optimization-based controllers for motion: use RRT* or OMPL for global planning, qpOASES/OSQP for whole-body QP solvers, KDL or TRAC-IK for inverse kinematics, and impedance control tuned between 100-1,000 N/m for compliant contact; instrument code with rosbag-style logs and per-loop sanity checks at 200-1,000 Hz.

Machine Learning Applications

Leverage supervised models for perception (ResNet-50 or MobileNet variants trained on ~10k labeled frames), imitation learning from 200-1,000 demonstrations for policy priors, and reinforcement learning (PPO/SAC) pre-trained in simulation for millions of timesteps then fine-tuned with 10-100 real trials; apply domain randomization and sensor fusion (RGB+depth) to narrow sim-to-real gaps.

Combine model-based and data-driven elements to improve sample efficiency: start with behavior cloning, then apply DAgger or offline RL to correct distributional shift, use pretrained vision backbones to cut labeling by >70%, run lightweight GP models (<1k points) for contact force prediction, and deploy quantized networks (INT8) on edge GPUs to sustain 30+ FPS perception pipelines.

Case Studies

Across real deployments, you see how explicit expert transfer affects performance metrics: error rates, cycle times, and verification burden. The examples below quantify impact across domains, showing where modular heuristics and supervised demonstrations produced measurable gains and where gaps in representation or safety validation created regressions.

- 1) Industrial assembly (Collaborative robot): Encoding 450 expert demonstrations reduced pick-and-place errors from 8.2% to 1.9% and cycle time by 14% across 12,000 parts over six months.

- 2) Surgical robotics (da Vinci-style teleop augmentation): A dataset of 1,200 annotated procedures improved automated suturing completion time by 15% and reduced intervention rate from 6% to 2.5% in trials of 300 cases.

- 3) Warehouse picking (mobile manipulator): Learning from 50 human pickers and 10,000 labeled grasps increased throughput by 22% and decreased mis-picks from 5% to 1.2% over a 90-day pilot.

- 4) Autonomous driving (teleoperation bootstrapping): Using 10,000 hours of human teleoperation, open-loop steering models cut driver interventions by 40% during staged urban tests totaling 5,000 km.

- 5) Agricultural weeding robot: Hybrid expert rules plus vision models across 30 hectares cut chemical usage by 70% and achieved 92% weed removal precision in three seasonal trials.

- 6) Nuclear inspection humanoid: Transferring three operators’ teleop strategies into autonomy reduced human exposure by 120 operator-hours and maintained inspection completeness at 98% across 40 missions.

Successful Examples in Robotics

You can replicate success by combining structured tacit knowledge with verification: one logistics deployment used 600 labeled failure modes and a rule-based fallback to achieve 99.3% task success over 25,000 operations. Applying modular heuristics allowed safe degradation, and you benefited from observing domain experts to identify edge cases that purely data-driven approaches missed.

Lessons Learned from Failed Attempts

You often see failures when representations omit rare but high-impact situations: a manipulation system trained on 5,000 demonstrations failed on 0.7% novel object geometries, causing stoppages that cost weeks of debugging. In those cases, lack of safety envelopes and insufficient expert-provided corner cases amplified risk and delayed deployment.

Digging deeper, you find three recurring root causes: under-specified expert knowledge (experts tacitly adapt strategies without articulating triggers), insufficient coverage of corner cases (training sets miss <1% but safety-critical conditions), and weak verification (no formal constraints or stress tests). Addressing each requires structured elicitation, targeted edge-case collection, and automated verification harnesses tied to your hardware limits.

Challenges and Limitations

Systems often hit limits from model mismatch, sensor noise, and the sim-to-real gap; benchmarks report 20-40% success-rate drops when transferring manipulation policies to hardware. You must handle unmodeled friction, actuator latency, and edge-case human heuristics that the robot never observed. For deeper reading on sensorimotor mappings and transfer workflows see From Human Hands to Robot Arms: Manipulation Skills ….

Barriers to Skill Transfer

Variability across experts and tasks creates generalization gaps: you might need 10-50 demonstrations per skill to reach acceptable performance, yet inter-operator differences produce inconsistent labels. Hardware constraints-payload, bandwidth, and sensing resolution-can force simplified controllers that lose finesse. Data collection costs can exceed 100 person-hours per complex assembly, and domain mismatch still breaks many imitation models.

Ethical Considerations

Safety standards like ISO 10218 and ISO 13482 require you to validate failure modes and maintain human override. Privacy concerns arise when capturing experts’ data-video, force traces, and biometrics-so you must anonymize or obtain consent. Liability is nontrivial: ambiguous attribution between designer, trainer, and deployer can complicate incident response.

Operationally, you should implement audit trails, explainable policies, and continuous monitoring; logs showing sensor inputs and decision points aid post-incident analysis. In regulated domains, auditors expect traceability and periodic revalidation-typically every 6-12 months-and quantitative risk reduction evidence (SIL-like metrics). Also plan workforce transition measures, such as retraining programs and role redesign, to mitigate displacement risks.

Conclusion

Drawing together the methods and insights presented, you can evaluate how expert demonstrations, cognitive models, and interactive teaching pipelines enable robots to acquire nuanced skills. By integrating sensor-rich capture, structured annotation, and iterative validation, you ensure your robotic systems learn robust, transferable behaviors that improve performance in dynamic tasks while maintaining safety and adaptability.