You will discover how AI-driven technology is transforming quality control in manufacturing. With the integration of advanced robotics, your production line can now detect flaws in real time, significantly enhancing efficiency and reducing waste. These intelligent systems leverage machine learning algorithms to identify defects faster and more accurately than traditional methods. As you explore this innovative approach, you’ll gain insights into the benefits and practical applications that can revolutionize your quality assurance processes.

The Role of AI in Quality Control

You can leverage AI technology to enhance your quality control processes markedly. By integrating advanced algorithms and data analysis, you ensure a higher accuracy in defect detection and overall product quality. AI minimizes human error and enables your operations to run more efficiently, reducing waste and increasing customer satisfaction.

Machine Learning Algorithms

Machine learning algorithms are at the core of AI-driven quality control. They analyze vast datasets to identify patterns and predict defects before they occur. For instance, a manufacturer can implement supervised learning to train models with historical production data, leading to real-time flaw detection that significantly reduces rework costs.

Data Analysis Techniques

Data analysis techniques play a pivotal role in optimizing quality control processes. Advanced analytics not only help in identifying defects but also in uncovering the root causes of quality issues. By employing statistical process control (SPC) and predictive analytics, your team can systematically improve production quality and consistency.

Data analysis techniques can be enhanced by incorporating tools such as Six Sigma and control charts, which provide visual cues for understanding process variations. By gathering real-time data from production lines and applying statistical methods, you gain actionable insights into operational inefficiencies. For example, the implementation of predictive maintenance powered by AI algorithms allows you to preemptively address machinery issues, streamlining your quality assurance efforts and ensuring your products meet strict quality benchmarks consistently.Real-Time Flaw Detection

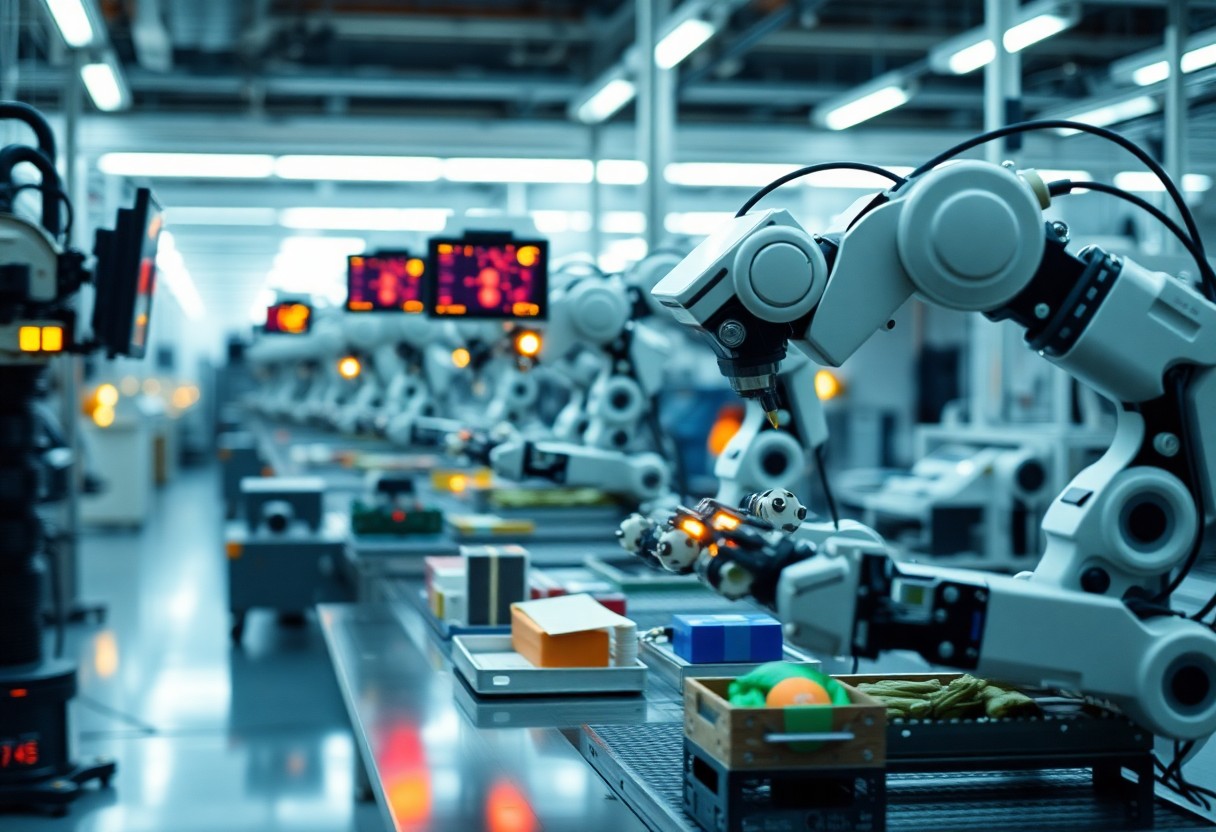

In manufacturing, real-time flaw detection enables your processes to respond immediately to defects, thereby reducing waste and enhancing product quality. By utilizing real-time AI-driven quality control for laboratory automation, systems can dynamically analyze production data, identifying anomalies at each stage. This proactive approach minimizes the risk of defective products reaching the market, ensuring compliance with industry standards.

Visual Inspection Systems

Visual inspection systems powered by AI methodologies deliver remarkable precision in quality assessments. These systems use high-resolution cameras and machine learning algorithms to scan products for imperfections while operating at speeds that surpass human capabilities. By capturing detailed imagery, these solutions learn to distinguish between acceptable and defective items, enabling you to maintain stringent quality standards across your operations.

Sensor Integration

Integrating sensors within your production line enhances the reliability of quality control measures by capturing real-time data about various parameters. These sensors can monitor factors such as temperature, pressure, and humidity, which are important for ensuring product integrity throughout the manufacturing process.

Your focus on sensor integration allows for synchronized data collection that complements visual inspections. For instance, temperature sensors can prevent malfunctions in processes sensitive to heat variance, while pressure sensors alert you to irregularities. When combined with AI analytics, sensor data provides comprehensive insights that help you quickly identify defects and optimize production efficiency. Case studies have shown that companies implementing integrated sensor systems coupled with AI have achieved a 25% reduction in defect rates, underscoring the importance of robust sensor networks in modern quality control frameworks.

Robot Implementation

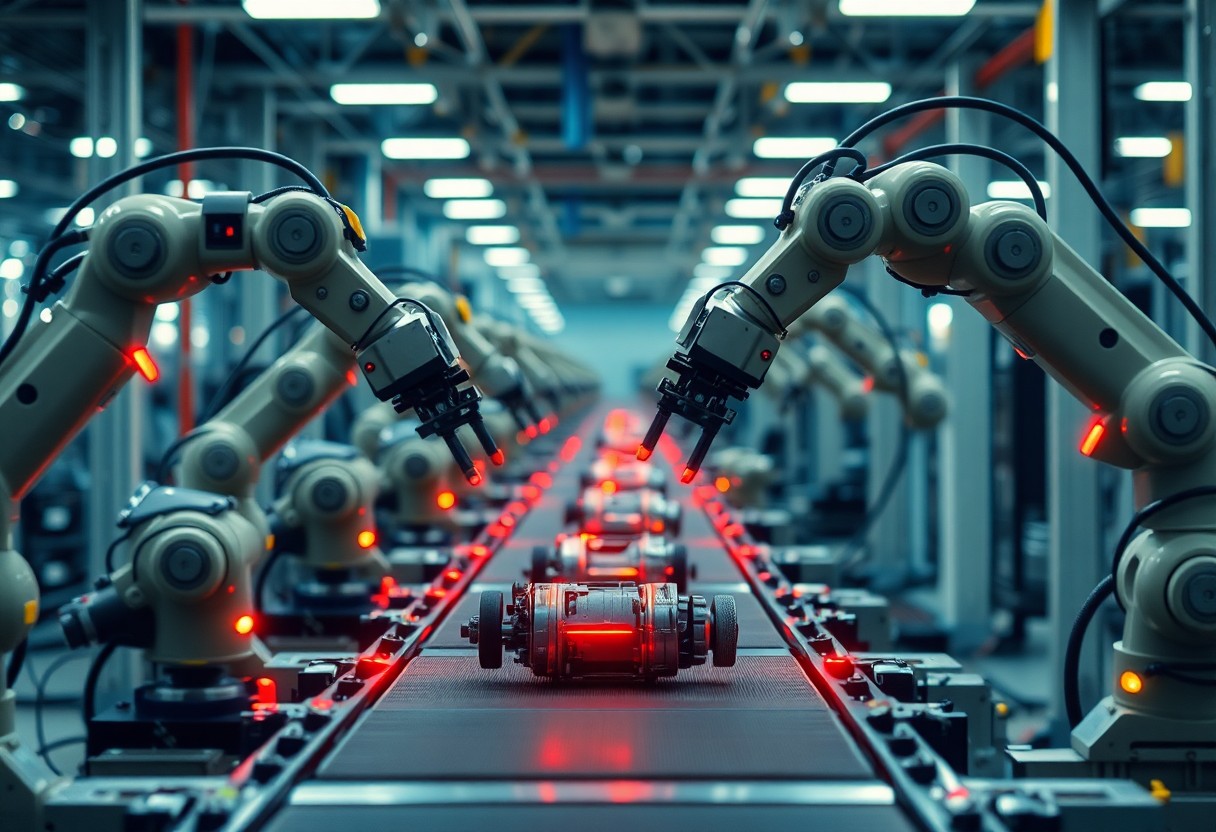

Implementing robots for quality control involves integrating advanced sensors and AI algorithms into existing manufacturing workflows. This transition allows for the seamless detection of defects during production, ensuring that only high-quality products reach the market. Companies can tailor these systems based on specific production needs, making the process adaptable and efficient.

Types of Robots Used

Various types of robots enhance quality control in manufacturing settings. You might encounter:

- Vision Systems – for optical inspection

- Collaborative Robots (Cobots) – for human-robot cooperation

- Autonomous Mobile Robots – for material handling

- Articulated Robots – for precision assembly

- Fixed Industrial Robots – for repetitive tasks

Thou can maximize output by choosing the right technology tailored to your production processes.

| Type of Robot | Key Feature |

| Vision Systems | High-resolution inspection |

| Collaborative Robots | Safe operation alongside humans |

| Autonomous Mobile Robots | Efficient material transport |

| Articulated Robots | Flexibility in movement |

| Fixed Industrial Robots | High-speed performance |

Automation in Manufacturing

Automation significantly enhances manufacturing efficiency and quality assurance. By leveraging AI-driven robots, you can streamline processes and reduce human error. These systems catch defects that a human might miss, ensuring a higher standard of output.

With automation, you witness a dramatic decrease in production times and wastage. For instance, a camera-equipped robot can inspect thousands of products per hour, identifying slight imperfections. Data analysis from these robotic systems provides insights that continually refine manufacturing processes, leading to sustained improvements in quality. Industries have reported increased throughput by up to 30% post-automation, showcasing the transformative potential of these technologies in your manufacturing operations.

Case Studies

Real-world implementations of AI-driven quality control highlight its effectiveness across various industries, demonstrating tangible benefits that enhance operational efficiency and product integrity.

- Automobile manufacturer X reported a 30% reduction in defective parts after implementing AI-powered inspection systems, leading to savings of over $2 million annually.

- Food processing company Y improved its quality assurance processes, resulting in a 40% decrease in product recalls due to defects, ultimately safeguarding its brand reputation.

- A leading electronics firm achieved a 99% accuracy rate in flaw detection by employing AI robots in its assembly line, markedly enhancing overall productivity.

- Pharmaceutical company Z utilized AI to detect anomalies in packaging, reducing error rates by 25%, which contributed to regulatory compliance and consumer safety.

Successful Implementations

Various industries have successfully adopted AI-driven quality control systems, significantly improving detection rates of defects and streamlining production processes. For instance, a major textile manufacturer utilized image recognition technology, achieving an impressive 95% reduction in human error during fabric inspections. This not only enhanced product quality but also increased throughput by 20%.

Lessons Learned

Insights from these case studies highlight the importance of ongoing training and adaptation in integrating AI technologies. Key factors for success include investing in employee education on new systems and fostering a culture that embraces technological change. The implementation process demands careful consideration of existing workflows to seamlessly integrate new tools without disrupting operations.

As organizations transitioned to AI-driven quality control, several lessons emerged. Many found that the initial investment in both technology and training paid off substantially, leading to faster returns. Engaging workers in the implementation process helped ease resistance and promote technology acceptance. Additionally, monitoring AI system performance post-implementation ensured consistent optimization and adaptability to evolving quality standards. This iterative approach significantly contributed to improved product quality and operational efficiency, reinforcing the critical role of AI in modern manufacturing landscapes.

Challenges and Limitations

Despite the advantages of AI-driven quality control, numerous challenges and limitations persist. Data privacy concerns, the initial cost of technology implementation, and the need for continuous system training can hinder progress. Additionally, the dependence on existing infrastructure and the variability in product design can complicate integration. As manufacturers strive for efficiency, addressing these issues is important to maximize the potential benefits of AI.

Technical Barriers

Integrating AI and robotics into quality control systems often encounters technical barriers such as insufficient data for training machine learning models and the complexity of real-time analysis. Inconsistent data quality can lead to inaccurate defect detection, making it imperative to create robust data management protocols before deploying these systems. Moreover, varied manufacturing environments may complicate algorithm applicability across different contexts.

Workforce Implications

While AI-driven quality control enhances efficiency, it also raises important workforce implications, particularly concerning job displacement and skill requirements. As robots take on quality assurance roles, many traditional positions may become obsolete, necessitating retraining programs to prepare your workforce for new technological demands. Skills in programming, data analysis, and robotics will be increasingly valuable, pushing for a significant shift in employee capability building.

The potential for job displacement is a pressing concern, as AI implementation could lead to a reduction in manual quality control positions. However, this transition also opens avenues for skilled jobs focused on AI management and technology maintenance. Companies that proactively invest in reskilling their employees can foster a workforce adept at leveraging AI tools, ensuring that human expertise complements automated systems rather than being replaced by them.Future Trends in AI-Driven Quality Control

The future of AI-driven quality control is set to be transformative, with innovations streamlining processes and enhancing precision. Factories will increasingly employ AI systems that utilize Leveraging AI-Powered Anomaly Detection to Transform … to identify anomalies faster and reduce waste, thereby maximizing efficiency and product integrity.

Emerging Technologies

Emerging technologies, such as machine learning algorithms and computer vision enhancements, are paving the way for real-time monitoring and predictive analysis in quality control. These advancements allow you to anticipate defects before they occur, shifting from traditional inspection to proactive measures that ensure higher quality standards across your production lines.

Industry Predictions

Industry predictions indicate that by 2025, up to 80% of quality control processes will leverage AI technologies, resulting in a 30% decrease in defects and a significant improvement in operational efficiency. As more manufacturers adopt these smart systems, companies that harness AI-driven inspection tools will gain a competitive edge in the fast-evolving marketplace.

The growing reliance on AI will also encourage advancements in data analytics, facilitating deeper insights into production trends and potential issues. With tools capable of processing vast amounts of data in real-time, companies can implement preventative measures and adapt quickly to market demands, ultimately leading to greater innovation and enhanced product offerings. This predictive approach signifies a shift from reactive quality control to a more integrated, strategic method of maintaining high standards and fostering continuous improvement.

Summing up

As you integrate AI-driven quality control into your operations, you’ll find that real-time flaw detection not only enhances product quality but also streamlines your manufacturing processes. The technology ensures that defects are identified promptly, reducing waste and improving overall efficiency. Embracing these advanced solutions positions you to stay competitive in an increasingly automated industry while allowing you to focus on strategic growth and innovation.