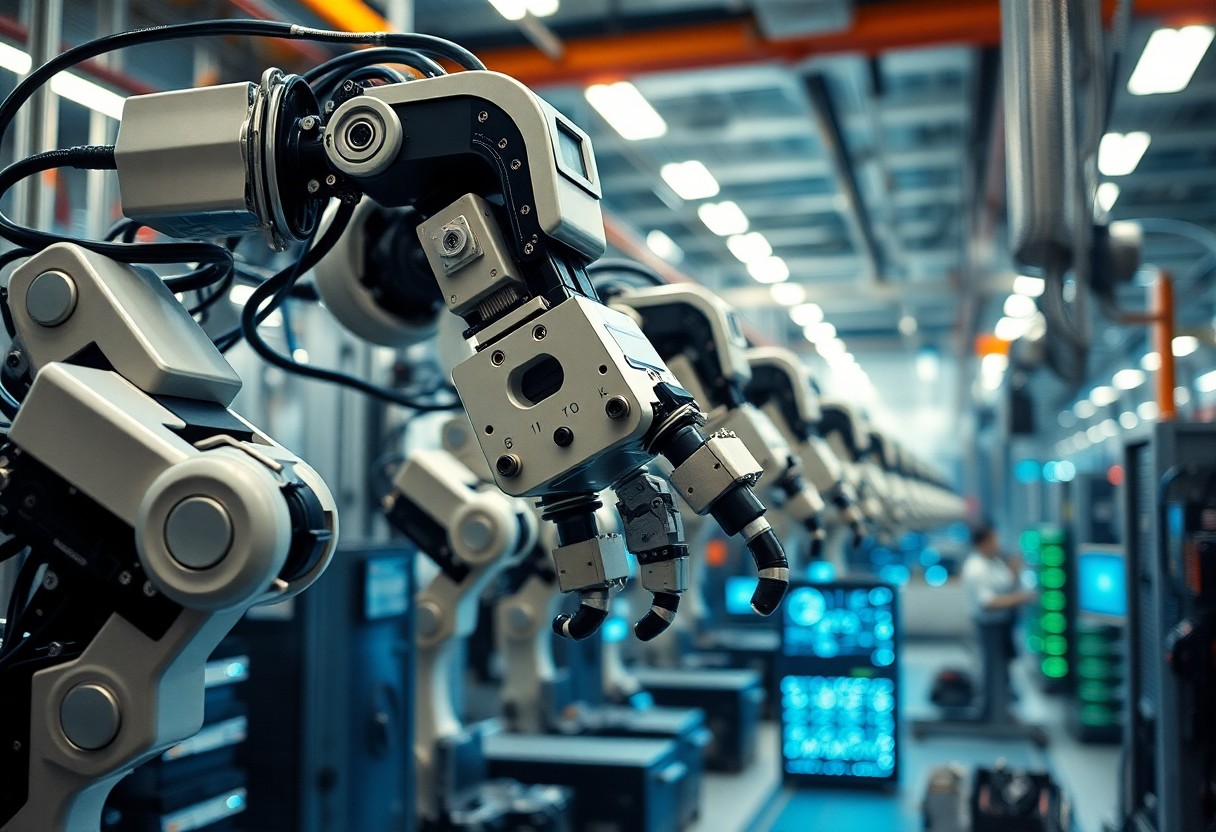

Automation is revolutionizing industries worldwide, and staying updated with the latest innovations in robotics is imperative for harnessing these advancements. In this blog post, you will explore cutting-edge technical parts that are driving efficiency, precision, and effectiveness in automation. From sophisticated sensors to smart actuators, you will learn how these innovations can significantly enhance your operations and improve overall productivity. Join us as we explore into the transformative technologies shaping the future of robotics and automation.

The Driving Forces Behind Automation Transformations

Several dynamic factors are catalyzing the evolution of automation in various industries. Advances in technology, shifts in market demand, and heightened consumer expectations are driving companies to integrate smarter solutions at an unprecedented pace. As you research deeper, you’ll uncover how these elements intertwine, reshaping not just production lines but entire business models.

Market Demand and Consumer Expectations

Your customers want products faster, cheaper, and of better quality than ever before. As consumer expectations rise, businesses must adapt to these demands or risk falling behind. The automation of processes, driven by the need for efficiency, allows companies to meet these challenges head-on, delivering higher quality and quicker turnaround times to consumers eager for innovation.

Technological Convergence

Multiple technologies are coming together in remarkable ways, enhancing automation capabilities. Robotics, artificial intelligence, and IoT are not stand-alone technologies anymore; their convergence creates a more powerful ecosystem that improves operational efficiency and effectiveness. As you embrace these converging technologies, your ability to leverage data and improve decision-making increases, ensuring your organization stays competitive.

Take, for example, the combination of IoT sensors and advanced robotics on production floors. By integrating these technologies, companies can analyze real-time data to preemptively address equipment malfunctions and optimize workflows. Machine learning algorithms can dynamically adjust robotic processes based on gathered insights, ultimately leading to significant cost reductions and productivity enhancements. Such synergies pave the way for smarter, more agile manufacturing, accelerating the pace at which you can meet changing consumer demands.

Smart Sensors: The Eyes and Ears of Robotics

Smart sensors represent a foundational component of modern robotics, allowing machines to perceive their environment with unprecedented accuracy. These advanced devices collect various forms of data, such as temperature, pressure, proximity, and motion, acting as the eyes and ears of robotic systems. With their ability to detect subtle changes in the surroundings, smart sensors enable automation technologies to make informed decisions, enhancing overall efficiency and safety in industrial applications.

Advances in Sensor Technology

Recent innovations in sensor technology have led to the development of more compact, cost-effective, and power-efficient devices. This includes systems using MEMS (Micro-Electro-Mechanical Systems) that deliver high sensitivity while reducing size. You can now find sensors capable of measuring not only basic environmental variables but also detecting complex patterns, allowing for greater flexibility in robotic applications—from manufacturing to healthcare.

Real-Time Data Processing Capabilities

The integration of advanced processing algorithms enables real-time data analysis, allowing robots to make split-second decisions based on incoming sensor data. This capability transforms how automated systems interact with their environment, facilitating tasks that require immediate responsiveness.

Real-time data processing capabilities can be seen in applications such as autonomous vehicles that rely on LiDAR and computer vision. These systems analyze information from multiple sensors simultaneously, allowing them to recognize obstacles, navigate complex environments, and respond to dynamic conditions in real time. As processing power continues to grow and algorithms improve, the potential for seamless interactions between robots and their environments expands significantly, paving the way for more intelligent sensors that can adapt and learn on the go.

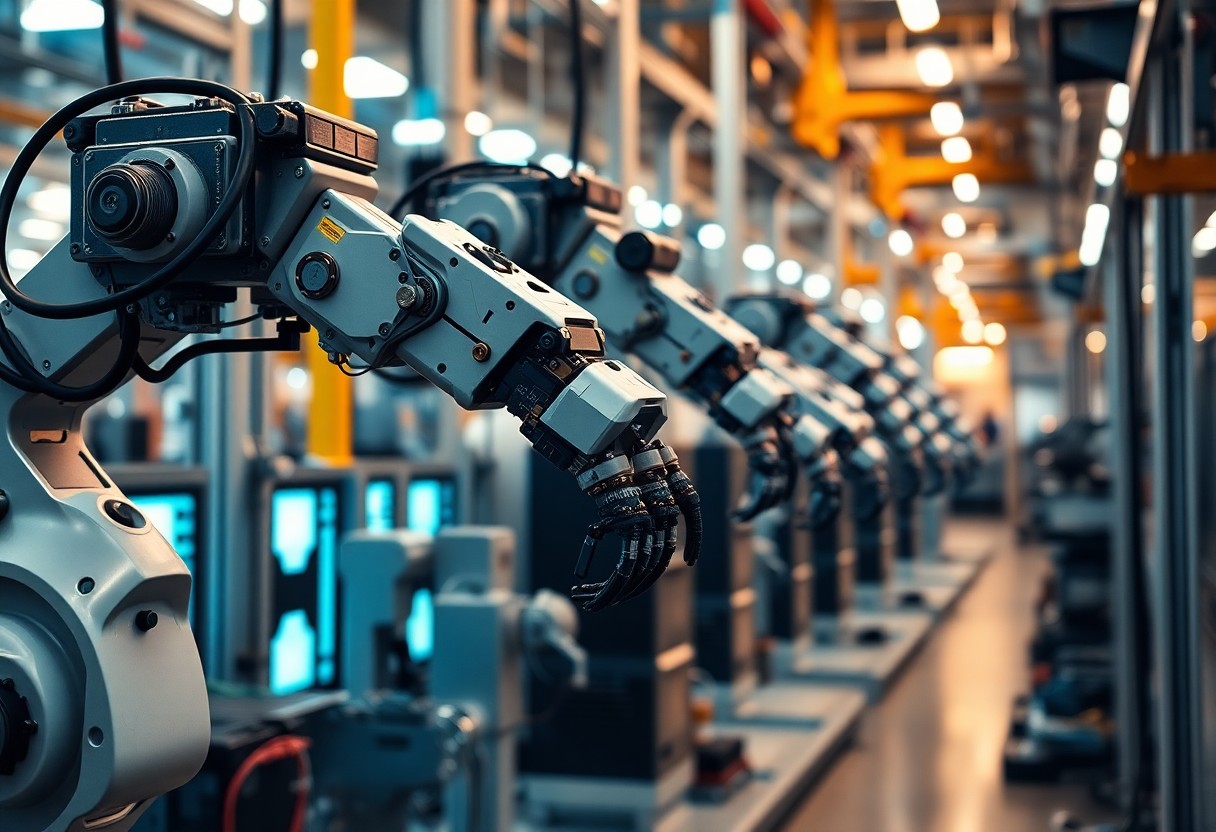

Modular Robotics: Adaptability for Diverse Functions

Modular robotics is revolutionizing automation by allowing for interchangeable components tailored to specific tasks. This adaptability not only enhances efficiency but also expands the capabilities of robotic systems across various industries. By integrating modular designs, robots can transform effortlessly to meet unique operational demands. This flexibility results in cost-effective solutions as detailed in Robotics: Breakthroughs in Automation.

The Benefits of Modular Design

One of the standout advantages of modular design lies in its efficiency. You can easily mix and match components to address different manufacturing processes without the need for a complete system overhaul. This scalability not only saves time but significantly reduces operational costs by maximizing resource utilization and minimizing downtime.

Innovations in Scalable Robotics Solutions

Recent innovations in scalable robotics have transformed the potential capabilities of automation systems. Advanced modular components can now be rapidly assembled or disassembled depending on the task, allowing you to adapt your robotic workforce in real-time to match production demands. This flexibility equips businesses to respond promptly to market changes while maintaining operational productivity.

One remarkable example of innovation in scalable robotics is the development of self-assembling robots that utilize smart materials and AI technology. These robots can autonomously adapt their structure and function based on environmental feedback, which means you can achieve higher levels of task specificity with less manual programming. Additionally, the use of swarm robotics is gaining traction, where multiple robots communicate and efficiently collaborate on complex tasks, further enhancing scalability and operational agility. With these advancements, your automation strategy can swiftly realign with the evolving landscape of industrial demands.

AI Integration: Enhancing Decision-Making Processes

AI integration into robotics significantly enhances decision-making processes, enabling systems to adapt and respond to dynamic environments with impressive precision. By leveraging advanced algorithms and vast datasets, robots can evaluate optimal strategies and make real-time adjustments, ultimately improving efficiency across various industries such as manufacturing, healthcare, and logistics.

Machine Learning in Robotic Systems

Incorporating machine learning into robotic systems allows for continuous improvement and skill adaptation. As robots gather more data from their environments, they can refine their actions and predictions, resulting in increased accuracy in tasks ranging from assembly line operations to autonomous navigation.

The Role of Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside humans, enhancing productivity and safety in the workplace. By sharing tasks, cobots allow for greater flexibility and complement human skills, leading to more efficient workflows.

Cobots are revolutionizing workplaces by augmenting human capabilities rather than replacing them. In manufacturing settings, for instance, these robots can handle repetitive tasks or heavy lifting, allowing workers to focus on more complex problem-solving and creativity. The flexibility of cobots enables them to be easily programmed and adapted for various functions, making them invaluable in diverse environments—from small workshops to large factories. Companies have reported up to a 30% increase in efficiency and a significant reduction in workplace injuries due to cobot integration, demonstrating their substantial impact on modern industrial practices.

Energy Efficiency: Powering the Future of Robotics

Advancements in energy efficiency are reshaping the robotics landscape, enabling longer operational times and reduced costs. By focusing on power consumption reductions in automation processes, businesses can enhance productivity while minimizing their environmental impact. Innovations in energy management systems and smart algorithms allow robots to optimize energy usage, creating a more sustainable approach to automation that bolsters your bottom line.

New Battery Technologies

Recent breakthroughs in battery technology are revolutionizing the capabilities of robotic systems. Lithium-sulfur and solid-state batteries, for instance, promise significantly higher energy densities compared to conventional lithium-ion options. This means your robots can operate longer without requiring frequent recharging, making them more efficient and reliable in demanding operational environments.

Sustainable Operational Practices

Adopting sustainable operational practices not only cuts costs but also enhances the eco-friendliness of robotic systems. Integrating renewable energy sources, such as solar or wind, to power your robotics can drastically reduce carbon footprints. Additionally, utilizing energy-efficient software algorithms and optimizing robotic movements to reduce energy waste further ensures that your automated solutions align with sustainable goals.

Implementing sustainable operational practices involves a shift in mindset regarding how you approach robotics in your organization. For instance, using predictive maintenance powered by AI can significantly extend the life of robotic components, reducing resource consumption and waste. Moreover, incorporating energy-efficient sensors and components helps create a synergy where enhanced performance aligns with lower environmental impact. By prioritizing these practices, you not only position your company as a leader in sustainability but also improve operational efficiency in ways that manifest directly on your balance sheet.

To wrap up

Now that you are aware of the latest innovations in robotics and the technical advancements in automation parts, you can better appreciate how these developments can enhance your processes and productivity. By integrating these cutting-edge technologies, you can stay ahead in a rapidly evolving landscape. Embracing automation is not just about efficiency; it’s also about positioning yourself for future growth and opportunity. Explore how these innovations can be applied within your industry to maximize your operational capabilities.