You are about to commence on an exciting journey into the fascinating world of robotics. This guide will help you understand the various types of robots that exist today, from industrial machines to adorable domestic helpers. By breaking down complex concepts, you’ll gain valuable insights into how these incredible machines operate and their applications in everyday life. Whether you’re looking to deepen your knowledge or explore career opportunities, this beginner’s guide will equip you with the foundational knowledge you need to navigate the diverse field of robotics.

The Diversity of Robotics: Categories Explained

Robotics encompasses a wide range of technologies and applications, each serving distinct purposes. Understanding the various categories of robots helps you appreciate their capabilities and enhancements in daily life. Whether for industrial tasks, healthcare, or everyday conveniences, each robot class brings its own unique attributes and functionalities. By delving into these categories, you can better grasp how robotics integrates into multiple sectors and advances modern experiences.

Autonomous Mobile Robots: Navigating the Environment

Autonomous mobile robots (AMRs) are designed to navigate their surroundings without direct human intervention. Equipped with sensors, cameras, and sophisticated algorithms, they can map their environment, plan routes, and adapt to obstacles in real-time. These robots are often used in logistics for warehouse operations, where they autonomously transport goods and optimize workflows.

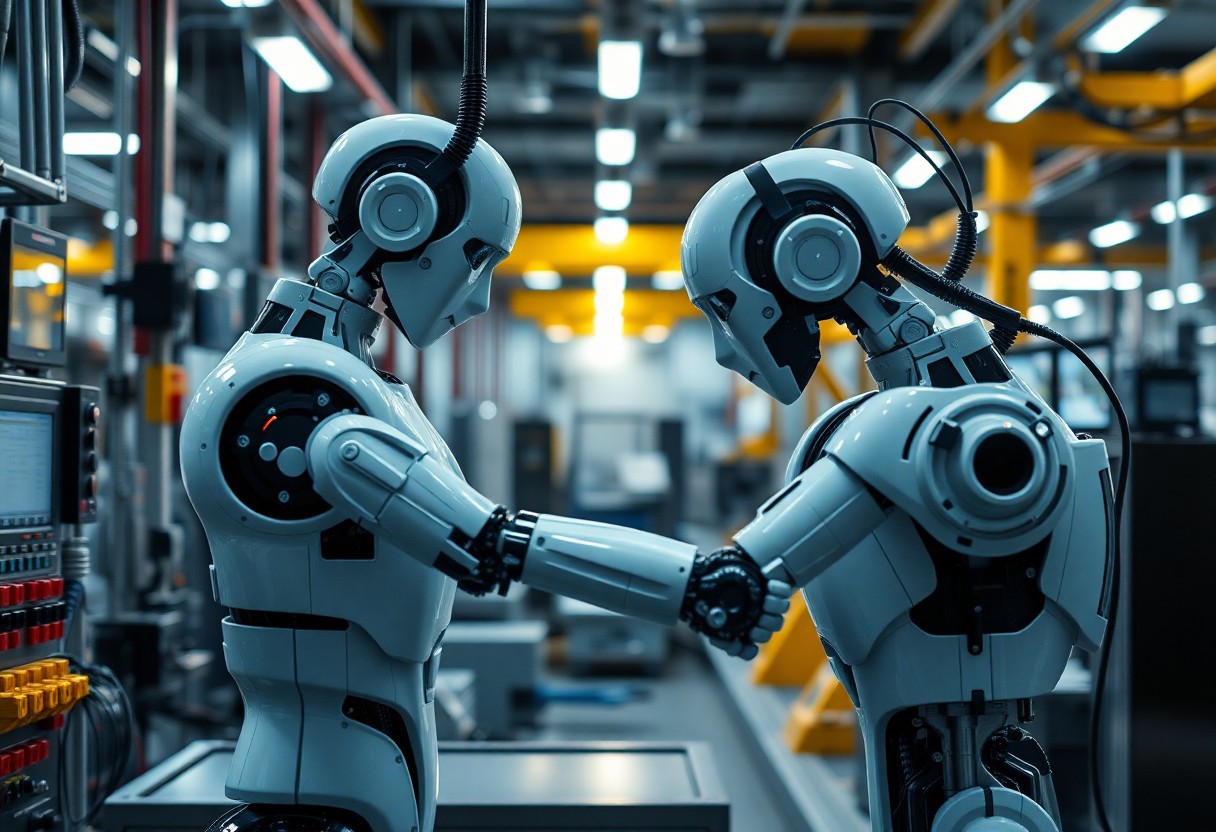

Manipulation Robots: Precision in Action

Manipulation robots are built to perform tasks requiring precision and dexterity, such as assembly, welding, or packaging. These versatile machines often mimic human hand movements, allowing them to tackle intricate and repetitive tasks with speed and accuracy. With advancements in robotics, modern manipulation robots are now capable of learning from their environment, improving their efficiency over time.

In industrial settings, manipulation robots have revolutionized manufacturing processes. For instance, in automotive assembly lines, robotic arms assemble components with pinpoint accuracy, significantly reducing production time and minimizing errors. The introduction of collaborative robots, or cobots, further enhances manipulation capabilities by working alongside human operators safely, taking on hazardous tasks while humans focus on nuanced processes that require human judgment. This synergy not only boosts productivity but also leads to safer work environments.

Service Robots: Enhancing Human Experiences

Service robots are increasingly becoming vital in various sectors, enhancing human experiences through automation. These robots assist in tasks ranging from healthcare support to hospitality, improving efficiency and service quality. For example, robotic vacuum cleaners in homes and delivery robots in hotels signify how service robots simplify daily tasks and enrich customer interactions.

The rise of service robots has transformed industries like healthcare, where robots help monitor patient vitals and assist in surgeries, ensuring higher standards of care. In restaurants and hotels, service robots greet guests, take orders, and deliver food, providing a unique dining experience. The integration of artificial intelligence allows these robots to understand and respond to human needs dynamically, shaping a future where technology seamlessly complements everyday life.

The Mechanics Behind Robot Functionality

Robots are intricate machines that rely on several key components to operate effectively. At the heart of each robot lies a combination of sensors, actuators, and control systems. These elements work in unison to help robots perceive their environment, execute tasks, and make decisions based on the data they collect, allowing for a wide variety of applications across different fields.

Sensors and Perception: Gathering the World’s Data

Sensors serve as the senses of a robot, enabling it to gather information from its surroundings. Common types of sensors include cameras, ultrasound, and lidar, each offering unique data collection capabilities. For instance, cameras convert visual information into data that a robot can process, while lidar provides precise distance measurements. These sensory inputs are fundamental for navigation, obstacle detection, and environmental interaction.

Actuators and Movement: Turning Ideas into Actions

Actuators are the components responsible for converting energy into motion, enabling robots to move and manipulate objects. They can be electric, pneumatic, or hydraulic, providing different levels of power and speed. For example, electric motors are often used for precise actions in robotic arms, while hydraulic actuators are ideal for heavy lifting tasks, showcasing the versatility required in robotic designs.

Concerning actuators, your design choices directly influence the robot’s capabilities and efficiency. Electric actuators are well-suited for precision tasks, such as picking up small components in manufacturing, where fine control is necessary. Pneumatic actuators, powered by air pressure, excel in applications needing quick movements, like in packaging automation. Hydraulic actuators provide high force, making them ideal for heavy-duty tasks, such as construction robots. Each type of actuator operates on different principles, therefore selecting the right one based on the task at hand impacts performance significantly.

Control Systems: The Brain Behind Robotics

Control systems act as the intelligence of robots, determining how they respond to sensor inputs and execute movements. This can involve both simple algorithms for basic tasks and advanced artificial intelligence for more complex decision-making. The programming behind control systems enables robots to adapt to various situations, improving their efficiency and effectiveness in performing designated tasks.

Your control system choices can determine a robot’s adaptability and responsiveness. For instance, simple open-loop control systems are effective for straightforward tasks, where precision isn’t paramount. In contrast, closed-loop systems utilize feedback from sensors to make real-time adjustments, allowing robots to optimize their actions based on changing conditions. This adaptability is crucial in dynamic environments, such as warehouses or assembly lines, where robots face unexpected challenges and need to adjust their strategies accordingly.

Innovations Driving Robotics Forward

Recent advancements are revolutionizing the robotics landscape, paving the way for smarter, more efficient machines. This surge in innovation encompasses various fields, from artificial intelligence to material science, reshaping the potential applications of robots. As you research into these innovations, you’ll discover how they enhance robot capabilities in diverse sectors, making them integral to modern life.

AI Integration: The Cognitive Revolution in Robotics

The fusion of artificial intelligence with robotics is creating intelligent machines capable of learning and adapting. With AI, robots can analyze vast amounts of data, make decisions in real-time, and operate autonomously in complex environments. This cognitive revolution is not only streamlining operations but also enabling robots to perform tasks alongside humans effectively.

Advances in Materials: Lightweight Yet Strong

The shift towards advanced materials is enhancing the structural integrity and efficiency of robots while significantly reducing weight. Innovations in composites and smart materials allow for the creation of robots that are both agile and durable, improving their performance across diverse applications.

Consider the use of carbon fiber and titanium alloys, which are being adopted in robotic designs to achieve an unmatched strength-to-weight ratio. This enables robots to perform heavy-duty tasks without being cumbersome, facilitating mobility and energy efficiency. In industries such as aerospace and automotive, such advances can improve the lifespan and capability of robotic systems, allowing for even more complex and demanding applications in the near future.

Robotics in Industry: Transforming Manufacturing

The integration of robotics in manufacturing is revolutionizing production processes. Automated systems equipped with precision tools are now commonplace, leading to faster production cycles while minimizing human error. You can see this transformation across various industries, from automotive assembly lines to electronics fabrication.

For instance, companies like Tesla and BMW have adopted robotic systems not just for assembling vehicles but for quality control checks and logistics as well. This shift has resulted in faster turnaround times and higher product consistency. Moreover, the data collected by robots during operations can be harnessed for predictive maintenance, dramatically reducing downtime and enhancing overall productivity. As manufacturers continue to embrace robotics, expect unprecedented advancements in efficiency and innovation.

The Ethical Landscape of Robotics

When engaging with robotics, you encounter a complex ethical framework that governs their development and deployment. Issues surrounding job displacement, decision-making responsibilities, and privacy concerns are at the forefront of this discussion. As robots become increasingly integrated into various sectors of society, understanding these ethical implications is important to navigate the changing landscape effectively.

Job Displacement vs. Job Creation: The Economic Balancing Act

The introduction of robots into the workforce raises significant concerns about job displacement. While automated systems can replace mundane tasks, they also have the potential to create new job opportunities in tech support, robot maintenance, and programming. Balancing these two forces is important for a fair transition into a robotic future, requiring proactive strategies from both governments and corporations to develop reskilling programs and emphasize innovation.

Autonomous Decision-Making: Who is Responsible?

In instances where robots make decisions independently, the issue of accountability surfaces. Questions arise regarding whether manufacturers, operators, or the robots themselves should bear responsibility for their actions. This dilemma necessitates a clear framework outlining legal and ethical responsibilities to ensure that victims of robot-induced errors receive appropriate recourse.

For example, consider autonomous vehicles. If a self-driving car gets into an accident, the determination of blame can be complicated. Are the manufacturers liable for programming flaws, or do you as the user hold responsibility for how the vehicle was operated? Establishing accountability in robotic systems requires careful examination of both legal structures and ethical considerations. Policymakers, developers, and users alike need to engage in discussions around safety standards and liability to navigate this evolving predicament effectively.

Privacy Concerns: The Surveillance Debate

As robots gain capabilities to collect and analyze data, privacy becomes a significant concern. The omnipresence of surveillance technologies, such as drones and security robots, raises questions about individual rights and freedoms. Finding a balance between security and personal privacy is pivotal to ensure that the benefits of robotics do not infringe upon your civil liberties.

For instance, facial recognition technology used in social robots can enhance security but simultaneously compromise personal privacy. As these technologies become more pervasive, there is an urgent need for regulations that safeguard your data rights and establish guidelines for ethical data usage. Vigilance in monitoring how robots interact with society is important to build trust and prevent potential overreach that could violate personal freedoms.

The Path to Becoming a Robotics Expert

Embarking on the journey to become a robotics expert involves a unique blend of education, skill development, and hands-on experience. You’ll navigate through various fields, including computer science, mechanical and electrical engineering, and artificial intelligence. Through practical application of theoretical knowledge, you’ll find yourself well-equipped to tackle the challenges in this dynamic industry. Understanding how to integrate various technologies is paramount to your success.

Essential Skills and Education: Crafting the Future Robotics Engineer

Your education path should include coursework in programming languages like Python and C++, as well as knowledge in physics and mathematics. Gaining familiarity with software tools such as ROS (Robot Operating System) and simulation software can greatly enhance your skill set. It’s important to pair theoretical learning with projects, where you can apply concepts in real-world scenarios to solidify your knowledge.

Resources and Communities: Where to Find Support

Finding the right resources and communities can significantly impact your growth in robotics. Online forums, local maker spaces, and academic clubs provide platforms for collaboration and learning. Websites like GitHub host numerous projects that can inspire and guide you on your journey, while platforms like Coursera and edX offer specialized courses to build your expertise.

Engaging with communities such as IEEE Robotics & Automation Society or local robotics clubs can provide support and networking opportunities. Often, these forums host competitions or workshops that allow you to practice your skills and gain feedback from like-minded individuals. Utilizing social media platforms, you can also connect with professionals and enthusiasts who share valuable insights and resources related to robotics.

Hands-On Projects: Learning by Building

Hands-on projects are important for applying your knowledge and gaining practical experience. Whether you construct a simple robotic arm or create an autonomous vehicle, these projects allow you to face real challenges and troubleshoot designs. Documenting your progress not only solidifies your learning but also builds a portfolio that can showcase your skills to future employers.

Engaging in competitions such as FIRST Robotics or building DIY kits from companies like Arduino or Raspberry Pi provides valuable learning experiences. Experimenting with open-source platforms enables you to tinker with existing designs and enhance them, fostering innovation. As you encounter challenges, the thrill of solving problems will deepen your understanding and make you a more versatile engineer, paving the way for a successful career in robotics.

Final Words

From above, you can see that understanding the diverse types of robots opens up a world of possibilities in technology and applications. By familiarizing yourself with the various categories, including industrial, service, and educational robots, you equip yourself with the knowledge needed to navigate this rapidly evolving field. Whether you’re aiming to pursue a career in robotics or simply wish to satisfy your curiosity, your journey into the world of robotics begins with grasping these fundamental concepts and their practical implications in everyday life.