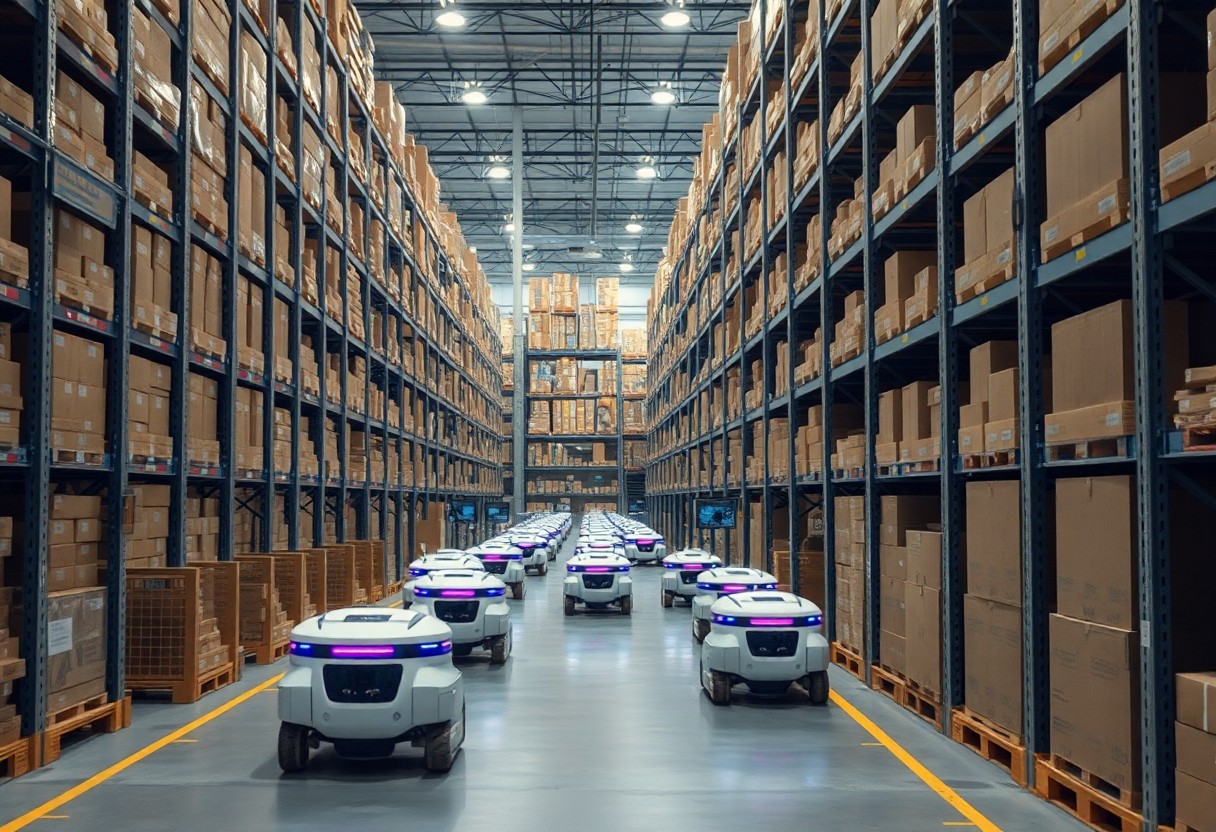

Robotics is transforming the logistics industry by introducing automated systems in warehouses, sorting facilities, and transport networks. You can leverage these advanced technologies to streamline operations, enhance efficiency, and reduce costs in your supply chain. From autonomous mobile robots that navigate warehouse floors to sophisticated sorting systems that optimize package handling, understanding the impact of logistics robotics will empower you to stay competitive in an evolving market.

Transforming Inventory Management with Robotics

Your inventory management processes can be revolutionized through the integration of robotics, which provides real-time visibility and control over stock levels. Automated systems streamline workflows, reducing human error and enhancing the overall efficiency of inventory operations. Using advanced algorithms and AI, these robots can analyze stock movements, predict demand, and optimize space, ensuring that you maintain the right amount of inventory at all times.

The Role of Automated Systems in Inventory Tracking

Automated systems have taken the lead in inventory tracking by employing RFID technology and barcode scanning to track items with precision. These systems continuously update your inventory records, allowing for accurate visibility of stock levels across multiple locations. With real-time data, you can swiftly adapt to changes in demand and avoid stockouts or overstock situations, ultimately enhancing your operational efficiency.

How Robotics Enhance Stock Accuracy and Efficiency

Robotics significantly boost your stock accuracy and efficiency by automating routine tasks associated with inventory management. Robots can conduct physical counts, update systems instantly, and assist with replenishment processes, minimizing manual errors that can lead to costly discrepancies. For instance, companies like Amazon have reported up to 25% improvement in retrieval accuracy through robotic implementation, directly translating to enhanced customer satisfaction and reduced excess inventory costs.

With the incorporation of robotics, you experience a transformation in stock accuracy due to the elimination of human variability in counting and data entry. For example, autonomous mobile robots (AMRs) equipped with sensors can seamlessly navigate through warehouses, conducting inventory audits and validating stock levels with a precision rate over 99%. This not only speeds up the inventory process but also enhances data integrity, allowing you to trust your stock reports. By continuously monitoring inventory levels and locations, robotics reduce the labor required for inventory checks, enabling your workforce to focus on more strategic operations, ultimately driving cost savings and improving service delivery.

The Revolution of Sorting Robots: Speed and Precision

Sorting robots are redefining operational efficiency by delivering unmatched speed and precise accuracy in warehouses. Unlike manual sorting, which can result in delays and errors, these advanced machines utilize sophisticated algorithms and artificial intelligence to classify and distribute items swiftly. In a typical logistics environment, sorting robots can achieve processing speeds of up to 3,600 items per hour, vastly enhancing productivity and reliability in supply chain operations.

The Mechanisms Behind Sorting Technology

Sorting technology relies on a combination of sensors, cameras, and machine learning algorithms to identify and categorize products. These systems analyze various attributes such as size, shape, and barcode information to facilitate accurate sorting. The integration of conveyor systems and robotic arms allows for seamless transfer of items to designated areas, ensuring optimal flow throughout the warehouse.

Real-World Applications of Sorting Robotics in Warehousing

Sorting robotics are actively utilized in warehouses of major retailers and e-commerce giants, significantly streamlining their operations. For instance, companies like Amazon and Walmart deploy these robots to improve order fulfillment rates and manage high volumes of inventory, revolutionizing their logistic frameworks. These implementations lead to higher accuracy rates, reduced labor costs, and quicker turnaround times for deliveries, showcasing the technology’s potential across the industry.

Sorting robots have transformed how modern warehouses operate by implementing automated sorting solutions. For example, Amazon’s use of Kiva robots has allowed them to increase efficiency and reduce the time taken to pick and pack orders. These robots not only minimize human error but also adapt to fluctuating order volumes, optimizing space utilization in warehouses. With real-time inventory management and assistance in peak periods, sorting robots exemplify how automation can ultimately enhance service levels and customer satisfaction in the logistics domain.

The Integration of Autonomous Transport Solutions

Integrating autonomous transport solutions streamlines operations and enhances efficiency across supply chains. You can expect a seamless flow of goods with the implementation of AMRs, minimizing human intervention while optimizing routes for faster delivery. This integration not only reduces operational costs but also scales effortlessly, adapting to fluctuating demands without compromising service quality.

Benefits of Autonomous Mobile Robots (AMRs) in Transport

AMRs offer significant advantages in transport logistics, including heightened efficiency, reduced labor costs, and improved safety. By automating repetitive tasks, you free your workforce for higher-value responsibilities, enhancing overall productivity. Moreover, AMRs showcase 24/7 operational capabilities, leading to expedited delivery times and increased inventory turnover rates.

Case Studies: Successful Implementations of Autonomous Transport

Numerous companies have successfully implemented autonomous transport solutions, yielding impressive results. For instance, global retail giants and warehouse operators have reported substantial increases in efficiency and reductions in labor costs, showcasing the transformative potential of AMRs in logistics.

- Amazon Robotics: Deployed 200,000 robots across its fulfillment centers, achieving a 20% increase in order processing efficiency.

- Domino’s Pizza: Integrated AMRs for food delivery, reducing delivery times by 30% and increasing customer satisfaction scores.

- Walmart: Implemented autonomous floor scrubbers in stores, resulting in a 10% reduction in operational costs and improved store cleanliness.

- BMW: Utilized AMRs in their factories, reducing parts transport time by 30% and enhancing assembly line productivity.

- ZF Friedrichshafen: Implemented autonomous transport vehicles, increasing material transport speeds by 40% in their manufacturing plants.

These case studies demonstrate how AMRs can revolutionize the logistics landscape. By analyzing data, you can see significant enhancements in efficiency and cost savings across diverse industries. Adopting autonomous transport solutions not only drives operational excellence but also positions your business for future growth in a rapidly evolving market.

Efficiency vs. Employment: The Robotics Dilemma

The advent of robotics in logistics brings a dual-edged dilemma: enhancing operational efficiency while raising concerns about workforce displacement. Automation increases productivity, enabling companies to process more goods at a faster rate, reducing costs and improving service levels. However, this shift poses tough questions regarding employment stability and the nature of work in these environments. Striking the right balance between utilizing advanced technology and ensuring job retention is becoming an necessary discussion in the logistics sector.

The Impact of Robotics on Workforce Dynamics

Robotics significantly alters workforce dynamics, reshaping roles and responsibilities within logistics operations. Some positions may diminish as machines take over repetitive tasks, but new roles in robot maintenance, programming, and oversight emerge. This shift necessitates reskilling and upskilling programs, allowing workers to transition into more technical or supervisory roles that complement automated systems.

Balancing Automation with Human Labor in Logistics

Finding a balance between automation and human labor in logistics involves strategic planning and investment in workforce development. Companies must assess which tasks can be automated without undermining employee welfare. Emphasizing collaboration between workers and robots can lead to enhanced productivity while preserving jobs. Implementing training programs will facilitate this transition, allowing workers to leverage their unique skills alongside robotic advancements.

Achieving harmony between automation and human labor requires a comprehensive approach. Logistics firms should focus on integrating robotic systems that handle mundane tasks, such as sorting or transporting, while allowing humans to engage in more complex decision-making roles. For instance, while robots expedite the sorting process, your role could shift to managing operations, ensuring seamless cooperation between man and machine. Furthermore, actively involving employees in the transition process fosters a culture of adaptability and technological comfort, ultimately enhancing overall efficiency and job security.

The Future Landscape of Logistics Robotics

As logistics robotics continues to evolve, you can expect a blend of AI-driven solutions and collaborative robots designed to enhance operational workflows. Embracing a more integrated approach in automated warehouses, these innovations will redefine efficiency and safety standards. For an in-depth look, refer to the 2024 Logistics Robotics Guide: Enhancing Efficiency with ….

Innovations on the Horizon: What to Expect

Coming advancements in logistics robotics include the rise of swarm robotics that mimic natural behaviors to improve coordination in warehouses. Enhanced AI algorithms will enable robots to learn from their environment and optimize delivery routes in real-time, further reducing operational costs. You may see autonomous vehicles equipped with advanced sensors improving last-mile delivery capabilities.

Challenges and Considerations for the Next Decade

Your journey into logistics robotics will not be without challenges. Factors such as high initial costs, cybersecurity risks, and regulatory hurdles will need careful navigation. Additionally, workforce adaptation and the need for reskilling workers will play significant roles in the successful implementation of these technologies.

High initial costs remain a significant barrier to entry for many businesses considering logistics robotics. For instance, implementing a fully automated warehouse system can require millions in upfront investment. Coupled with potential cybersecurity threats as operations become increasingly digitized, companies face a balancing act between innovation and security. Regulatory compliance can also be complex, as varying jurisdictions have different requirements for robotics use within logistics. Adapting your workforce is crucial too; investing in employee training and support will facilitate the transition and ensure that human and robot collaboration enhances productivity, rather than stifles it.

Summing up

So, as you explore logistics robotics, you’ll discover how automated warehouses, sorting, and transport robots can enhance your operational efficiency. By integrating these technologies, you can streamline processes, reduce labor costs, and improve accuracy in inventory management. Embracing robotic solutions enables you to stay competitive in an evolving market, ensuring that your logistics operations meet the increasing demands for speed and precision.