With the advent of collaborative robots or cobots, small and medium enterprises (SMEs) can enhance productivity and efficiency in their operations. These user-friendly machines are designed to work alongside your team, improving workflows without the need for extensive training or technical expertise. By integrating cobots into your processes, you can not only streamline tasks but also optimize workforce allocation, allowing your employees to focus on more strategic initiatives. This guide will explore how cobots can revolutionize your SME and drive growth in today’s competitive landscape.

Understanding Collaborative Robots

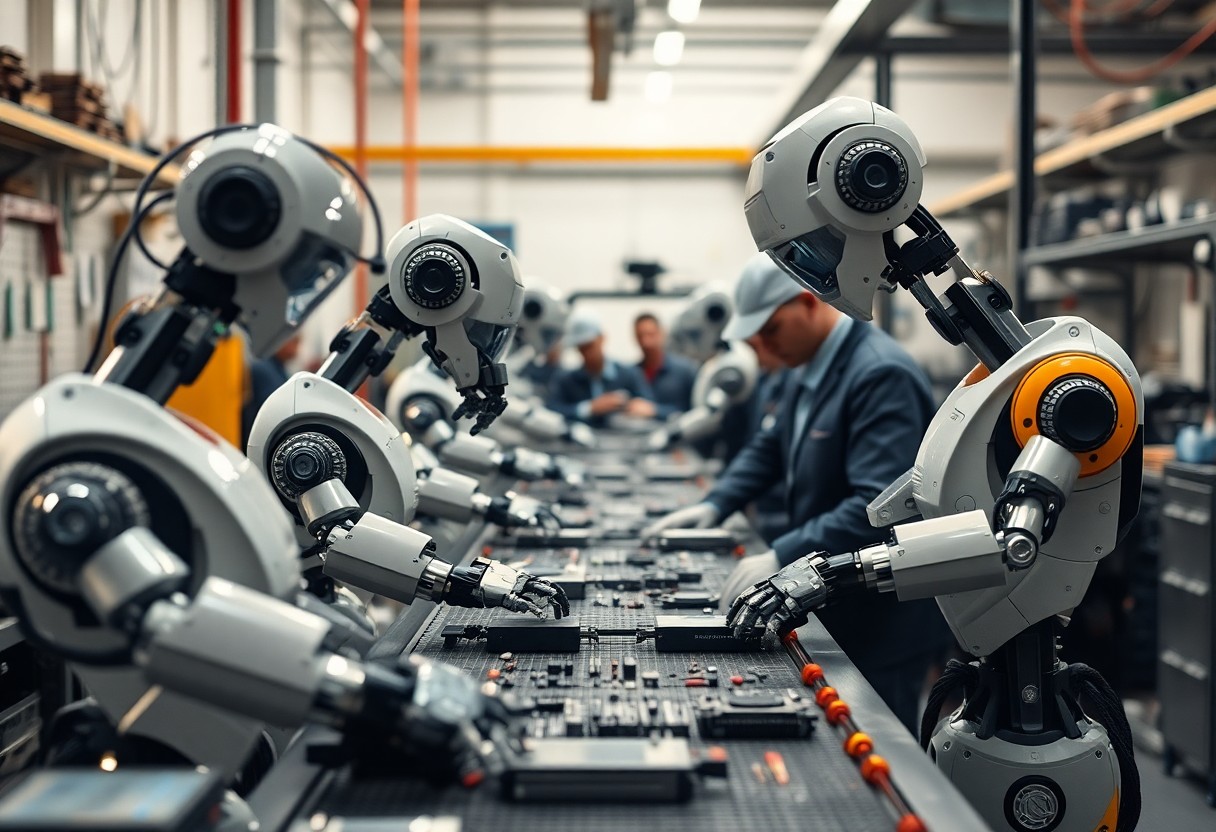

Collaborative robots, or cobots, are designed to work alongside humans, enhancing productivity and safety in various industries. Their advanced sensors and intuitive programming allow them to assist in tasks without the need for safety cages, making them suitable for small and medium enterprises (SMEs). As you integrate cobots into your operations, you can streamline processes and empower your workforce with these user-friendly technologies.

Definition of Cobots

Cobots are robotic systems engineered to collaborate with human workers in shared spaces. Unlike traditional industrial robots, cobots operate safely alongside people, adapting seamlessly to workflow changes. Their versatility makes them ideal for applications ranging from assembly line tasks to packaging and quality control in SMEs.

Difference Between Cobots and Traditional Robots

The primary distinction lies in their operational design. Traditional robots typically require designated workspaces separated from humans due to safety concerns, while cobots are equipped with sensors and algorithms that enable safe interactions, allowing them to share workspaces without barriers.

This difference in design philosophy significantly impacts workflow efficiency. Traditional robots often execute repetitive tasks without flexibility, making them less adaptable in dynamic environments. Cobots, on the other hand, can learn new tasks quickly through user-friendly programming and can be easily re-deployed to accommodate shifting production needs. This adaptability fosters a collaborative atmosphere where workers and machines complement each other’s strengths, ultimately enhancing productivity in your operations.

Benefits of Cobots for Small and Medium Enterprises

Integrating collaborative robots (cobots) significantly enhances operational capabilities within small and medium enterprises (SMEs). These versatile machines boost productivity, improve worker safety, and streamline processes, allowing you to allocate resources more effectively. With cobots, you can handle repetitive tasks with precision, freeing your employees to focus on more complex and value-added activities. The adaptability of cobots ensures they suit various industrial environments, making them an ideal choice for SMEs aiming to remain competitive.

Increased Efficiency

Cobots enhance efficiency by performing repetitive and time-consuming tasks faster and with greater accuracy than human workers. This allows your team to maximize output and minimize errors, significantly boosting overall operational productivity. By seamlessly integrating into existing workflows, cobots can work alongside employees, optimizing processes without the need for complete operational overhauls.

Cost-Effectiveness

Investing in cobots leads to substantial cost savings for your business. The initial procurement costs are often offset by reduced labor costs, as cobots can operate efficiently without the need for extensive breaks or overtime. Additionally, cobots can work around the clock, further increasing productivity without incurring higher operational expenses. Over time, the return on investment becomes evident through improved output and lower labor turnover.

Over the last few years, many SMEs have reported that cobots help reduce labor costs by approximately 30% while increasing production speeds by 20%. For example, a small manufacturer implemented a cobot to assist in assembly tasks, leading to a noticeable drop in operational costs due to fewer human errors and diminished overtime pay. These efficiencies accumulate, providing a financial buffer that allows for growth and development while maintaining a competitive edge in the market.

Applications of Cobots in SMEs

Manufacturing

Cobots in manufacturing enhance production efficiency by automating repetitive tasks while collaborating with human workers. You can deploy these robots for assembly, welding, and quality inspection, significantly reducing cycle times and minimizing human error. For instance, a small electronics manufacturer utilized cobots for circuit board assembly, achieving a 30% increase in output with improved precision.

Warehousing and Logistics

In warehousing and logistics, cobots streamline operations by automating picking, packing, and inventory management. You benefit from reduced labor costs and enhanced accuracy. Many SMEs have integrated cobots into their systems, resulting in faster order fulfillment and improved space utilization.

For example, a mid-sized logistics company equipped its warehouse with cobots that assist in transporting goods from storage to packing areas. This integration allowed employees to focus on more complex tasks, improving overall productivity by 25%. Additionally, cobots can operate continuously without fatigue, ensuring that operations run smoothly during peak hours, thereby boosting your ability to meet customer demands efficiently.

Challenges in Implementing Cobots

Several challenges arise when implementing cobots in small and medium enterprises, impacting their successful integration into existing workflows. Addressing these challenges requires careful planning and consideration of technical, financial, and organizational factors that can influence the overall effectiveness of cobot deployment.

Initial Investment Costs

The initial investment costs for cobots can be a barrier for many SMEs. While the average price of a cobot ranges from $20,000 to $50,000, additional expenses for software, training, and infrastructure can significantly increase the total investment, leading to concerns about return on investment.

Workforce Integration

Integrating cobots into your workforce presents unique challenges, especially regarding employee adaptability and job displacement concerns. Your team may need training to interact effectively with cobots, and fostering a collaborative environment is necessary for realizing the full benefits of automation.

Successful workforce integration involves open communication about the roles of cobots and addressing fears around job loss. Providing training programs that enable your workers to upskill and work alongside cobots can enhance productivity. For example, at a European automotive SME, employee-driven discussions about cobot roles led to a 30% increase in production efficiency and reduced turnover rates. By positioning cobots as tools to assist rather than replace, you create a positive work culture that encourages innovation and collaboration.

Selecting the Right Cobot for Your Business

Choosing the right collaborative robot (cobot) involves evaluating your specific operational needs, workspace, and budget. Factors such as payload capacity, reach, and ease of programming should guide your decision. Assess potential applications and ensure the chosen model aligns with existing systems. For insights on how cobots are reshaping industries, check out How Collaborative Robots Cobots Are Transforming U.S. Manufacturing.

Key Considerations

Evaluate the specific tasks your cobot will perform, including the level of precision required and the environment in which it will operate. Consider scalability to accommodate future growth, as well as integration capabilities with your existing machinery. Factor in the ease of programming and user-friendliness to ensure your team can adapt quickly.

Popular Cobot Models

Several cobot models cater to different needs in small and medium enterprises. The Universal Robots UR3, UR5, and UR10 are versatile, offering varying payload capacities. The cobots from Makerbot and Rethink Robotics feature intuitive programming systems, making automation accessible even for non-technical staff. Additionally, FANUC’s CR-series is known for reliability in high-demand environments.

Among the popular models, Universal Robots’ UR series stands out for its flexibility and ease of use, making it ideal for small businesses looking to embrace automation without extensive training. Additionally, the collaborative capabilities of FANUC’s CR series support tasks from assembly to packing while maintaining safety protocols. The integration of advanced vision systems in models like the Baxter from Rethink Robotics also enhances operational efficiency, allowing for greater adaptability in dynamic workspaces.

Future Trends in Cobot Technology

The future of collaborative robot (cobot) technology is marked by rapid innovation and integration into various sectors. As you look ahead, advancements in artificial intelligence and machine learning will enable these robots to become more autonomous, adaptable, and capable of complex tasks. Enhanced sensor technologies will allow cobots to interact more safely and effectively with human workers, potentially transforming the workspace dynamics in small and medium enterprises.

Advancements in Capabilities

Exciting advancements in cobot capabilities are reshaping their functionality within small and medium enterprises. Enhanced vision systems and improved dexterity enable these robots to handle increasingly intricate tasks with precision. This empowers you to deploy cobots in diverse roles, from assembly line work to quality assurance, driving both productivity and accuracy in your operations.

Growing Market Adoption

Market adoption of cobots is accelerating as more SMEs recognize their potential to boost productivity and lower operational costs. In recent years, surveys indicate that over 50% of small businesses are considering cobot integration, driven by a growing awareness of their ease of use and flexibility. The favorable return on investment seen in early adopters further propels this trend.

The rising integration of cobots in various industries illustrates a tangible shift in operational strategies among SMEs. With automated solutions becoming more user-friendly and affordable, businesses of all sizes are beginning to embrace this technology to streamline workflows. For instance, companies that implemented cobots reported productivity increases of up to 40%, highlighting the competitive advantage they provide. As more SMEs share their success stories, you may find that the reluctance to adopt cobots diminishes, paving the way for widespread incorporation across your industry.

Final Words

The integration of collaborative robots, or cobots, in small and medium enterprises empowers you to enhance productivity and efficiency while fostering a safe working environment. By collaborating alongside human workers, these versatile machines can handle repetitive tasks, allowing your team to focus on higher-value activities. Embracing cobots not only streamlines your operations but also positions your business competitively in an evolving market. As you explore automation options, consider how cobots can seamlessly blend into your workflow, driving innovation and growth.