Most robots increasingly learn on the job, and you should know how continuous adaptation uses online learning, sensor-driven feedback, and safety-aware updates to maintain performance in real environments; this post explains methods, evaluation metrics, and operational considerations so you can deploy and monitor adaptive systems effectively in your operations. The Importance of Continuous Learning In […]

Author: Mr. Robot

Multi-Modal Perception – Seeing, Hearing, and Touching Robots

With advances in sensor fusion, learning algorithms, and tactile materials, you can enable your robots to perceive environments through sight, sound, and touch simultaneously; this multimodal approach improves reliability, situational awareness, and human-robot interaction by combining complementary cues, mitigating single-sensor failures, and enabling richer object understanding, navigation, and collaborative manipulation in real-world settings. The Basis […]

General-Purpose Robots Move Closer to Commercial Reality

With advancing sensors, modular software, and falling hardware costs, you can expect general-purpose robots to enter real-world workspaces sooner than many predict; understanding their capabilities, limitations, and integration requirements helps you plan for enhanced productivity, safer workflows, and new business models as manufacturers and service providers scale deployment across industries. Current State of Robotics In […]

Foundation Models for Robotics – One Brain, Many Machines

With foundation models, you can unify perception, planning, and control across diverse robots by leveraging shared representations and transfer learning; this single “brain” accelerates adaptation, reduces engineering overhead, and enables scalable coordination so your fleet learns faster, generalizes better, and executes complex tasks with greater consistency and safety. Overview of Foundation Models You can now […]

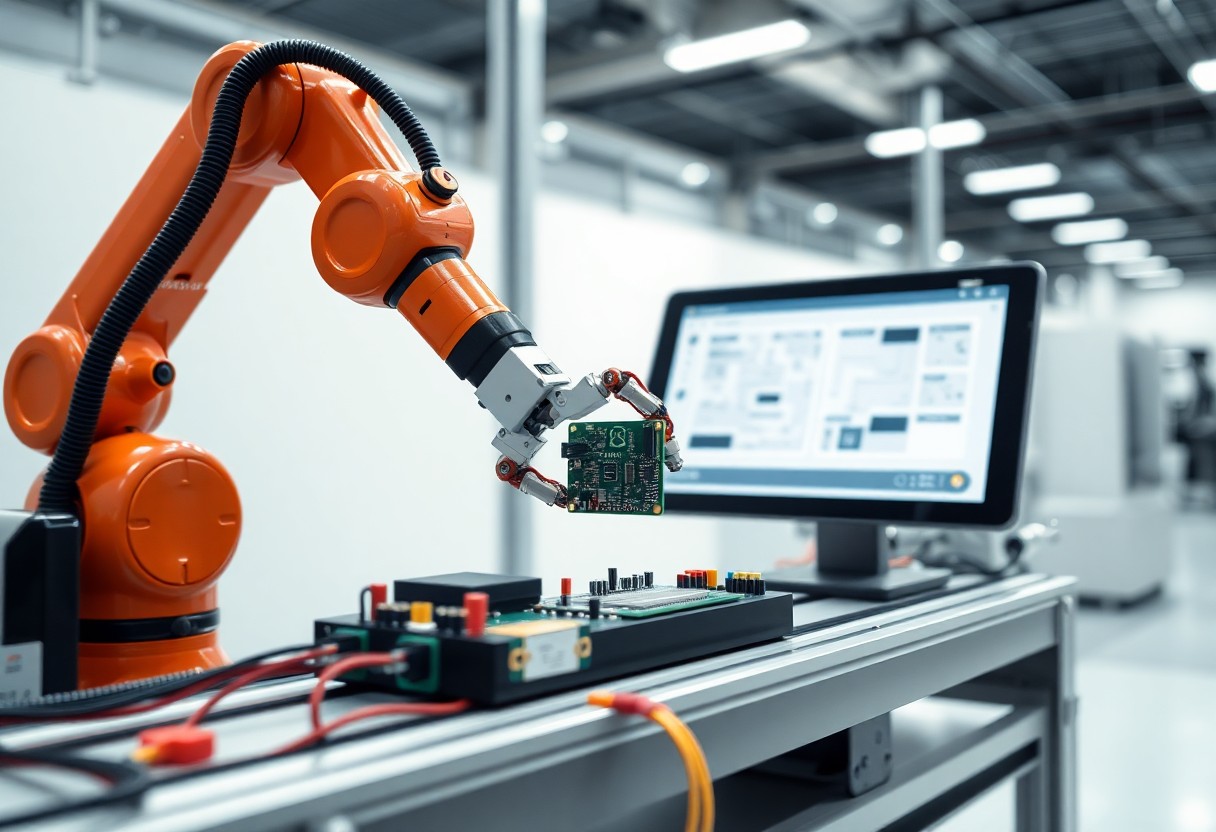

High-Precision Robotics Enable the Next Wave of Semiconductor Manufacturing

You rely on high-precision robotics to push semiconductor manufacturing beyond current limits, enabling nanometer-scale alignment, repeatable throughput, and adaptive motion control that reduce defects and increase yield. This post explains how advanced sensors, machine learning, and compact actuators integrate to automate lithography, wafer handling, and inspection, letting your fab scale performance while lowering variability and […]

Autonomous Factories – From Isolated Cells to Fully Orchestrated Systems

There’s a shift in manufacturing as isolated automated cells evolve into fully orchestrated autonomous factories, and you need to understand how integration, real-time data, and adaptive control transform productivity and resilience. This post explains the technology stack, system architectures, workforce impacts, and implementation pathways so you can evaluate readiness, prioritize investments, and lead deployment of […]

Cybersecurity for Robots – Protecting Autonomous Systems from Attack

Cybersecurity for robots requires you to integrate threat modeling, secure boot, authenticated firmware updates, encryption, and robust access controls so your systems resist tampering and data theft; you must enforce network segmentation, continuous monitoring, rapid patch management, and fail-safe behaviors while validating third-party components to keep autonomous systems reliable and safe under attack. Understanding Cybersecurity […]

Zero-Programming Robotics – Automation Without Coding

You can deploy and manage robotic systems without writing code by using visual programming, drag-and-drop interfaces, and prebuilt modules; this lets you optimize your workflows, integrate sensors and actuators, and scale solutions rapidly while minimizing technical barriers and time to value. Understanding Zero-Programming Robotics Definition and Key Concepts You build robot behavior through visual tools-drag-and-drop […]

Robotics in Construction – Automating the Built Environment

With robotics transforming tasks from heavy lifting to precision assembly, you can deploy autonomous equipment, drones, modular fabrication, and AI-driven planning to boost productivity, improve safety, and reduce cost variability; this post explains key technologies, implementation challenges, and practical steps for integrating robotics into your projects so you can plan, manage, and scale automation in […]

Robotics in Food Processing – Automation Meets Customization

Automation is rapidly redefining robotics in food processing, enabling you to scale operations with precision, consistency, and improved hygiene while adapting lines to varied recipes and formats. Robotic vision, AI-driven control, and modular tooling let your facility handle high-mix, low-volume runs, shorten changeovers, and enhance traceability, quality control, and worker safety. Implemented strategically, robotics both […]